1.Advantages uye kuipa kwelaser welding muchina uye chiyero chekushandisa kwayo

Laser welding muchina imhando nyowani yewelding nzira, ine yakaderera bond simba, kupisa-inokanganisa nzvimbo yakafara uye zvimwe zvakawanda zvakanaka, mumusika wazvino wesimbi wekugadzira simbi, laser welding yakashandiswa zvakanyanya, yagara ichishandiswa mune ese mafambiro ehupenyu. , senge: kapu yekuisa simbi, indasitiri yenharembozha, indasitiri yezvokurapa, indasitiri yemotokari uye mamwe akawanda maindasitiri zvikamu.

01 Zvakanakira zvelaser welding muchina

Kuenzaniswa neyechinyakare welding tekinoroji, laser welding tekinoroji haisi yekubata welding, maitiro ekuvhiya haadi kudzvanywa, ane kukurumidza welding kumhanya, kusimba kukuru, kudzika, kudiki deformation, nhete weld seam, diki kupisa-yakakanganiswa nzvimbo, uye workpiece. deformation idiki, iyo yekutevera-yekugadzirisa basa basa ishoma, kuderedza kuburitswa kwemanyorero, kuchinjika kwepamusoro, kuchengetedzwa kwakawanda uye zvimwe zvakanakira.

Laser welding tekinoroji inogona kushandiswa kupinza refractory zvinhu senge yakakwira simbi inonyungudika, uye kunyangwe isiri-simbi zvinhu zvakaita seceramics uye organic girazi, ine yakanaka welding mhedzisiro pazvinhu zvakaumbwa uye kuchinjika kukuru. Kune welding zvikamu zvisingasvikike, flexible transmission non-contact welding inoitwa. Iyo laser beam inogona kupatsanurwa munguva uye simba, ichigonesa panguva imwe chete kugadziridzwa kwematanda akawanda, ichipa mamiriro ekunyatso kukwenenzvera.

02 Mapoinzi ekucherechedza pakushandiswa kwelaser welding michina

Izvi zvinotevera zvinhu zvinofanirwa kucherechedzwa kana uchishandisa laser welding muchina michina

(a) Chinzvimbo chechikamu chakasungwa chinoda kunyatsojeka, kuve nechokwadi chekuti chiri mukati mekutarisa kwedanda relaser.

(b) Kana chikamu chakasungwa chichida kushandiswa kwechigadziriso, chinofanirwa kuve nechokwadi chekuti nzvimbo yekupedzisira yechikamu chakasungwa chinoda kuenderana nenzvimbo yeweld panozokanganisa danda re laser.

(c) Ukobvu hwepamusoro hunosungirirwa hushoma, kupinda kwezvishandiso zvine ukobvu zvakanyanya kupfuura 19mm mumutsetse wekugadzira kunoda kubvunzana nemugadziri kuti ape humwe hunyanzvi hunyanzvi rutsigiro.

03 Zvishandiso zvelaser welding michina

1. Battery industry

Nharembozha uye yakawanda yekodhi zvigadzirwa zvebhatiri zvinoshandiswa laser welding.

2. Bathroom kitchenware industry

Laser welding precision ine chitarisiko chiri nani, saka mune yepamusoro-giredhi yekugezera Stainless simbi zvigadzirwa laser yekumaka laser welding ine huwandu hwakawanda hwekushandisa. Zvakadai se: zvibatiso, mapombi, mapanga ekucheka asina tsvina uye yakawanda yenzira ine laser yekumaka yekugadzirwa kwekambani LOGO, epamusoro-giredhi kettle yemagetsi uye zvimwe zvisimbiso zvinoshandisawo laser welding kupedzisa. Kitchenware, tableware group welding butt welding, yakavhurika mold mold kugadzira uye kugadzirisa uye shandura mold mukuita kwekushandisa.

3. Zvigadzirwa zvedhijitari, nharembozha, indasitiri yemakomputa

Kugadziriswa kweLaser nekuda kweiyo chaiyo yekugadzirisa tekinoroji, mudhijitari, nharembozha, komputa mashandisirwo anozivikanwa se: nharembozha, MP4, MP3 shell laser welding, interface mutsara, laptop makomputa, fiber optic zvishandiso nzvimbo welding, komputa chassis yekubatanidza welding. .

4. Injiniya yemichina yeindasitiri

Kucheneswa midziyo welding, electromechanical zvikamu welding, connector kutakura kugadzirisa.

5. Electronics, indasitiri yemagetsi

Sezvo laser processing iri isiri-yekubata yekugadzirisa nzira, haiburitse mechanical extrusion kana mechanical stress, saka inonyanya kusangana nezvinodiwa zvekugadzirisa zveindasitiri yemagetsi. Zvakadai se: transformers, inductors, connectors, terminals, fiber optic connectors, sensors, transformers, switches, mabhatiri efoni, microelectronic components, integrated circuit lead uye mamwe mabheti.

6. Jewelry industry

Sezvo laser process yakanaka kwazvo, yakanakira zvigadzirwa zvakakosha uye zvidiki muindasitiri yezvishongo. Sezvo danda rakatariswa nelaser rakanyanya kunaka, rinokwidziridzwa nemaikorosikopu kukudza zvidimbu zvidiki zvezvishongo uye kuona kukwenenzvera. Iyo laser spot welder chishandiso chinodiwa chekubatanidza cheni dzezvishongo uye kuiswa kwematombo anokosha.

7. Hardware, zvishandiso, indasitiri yezviridzwa

Chiridzwa, sensor, kitchenware, tableware boka welding butt welding, yakavhurika mold kugadzira uye kugadzirisa uye shandura mold panguva yekushandiswa. Seamless welding ye Stainless steel tableware, welding pakubatana kwemamita core.

8. Motokari, indasitiri yemotokari yemagetsi

Laser processing yeasina-contact processing, hapana kusvibiswa kune chigadzirwa, kumhanya kwakanyanya, kwakakodzera kune zvinodiwa zvemhando yepamusoro-yekupedzisira yemotokari yevatengi kugadzirwa kwezvinhu, senge mota dial welding, valve welding, piston ring welding, mota silinda gasket welding, exhaust pombi, kusefa welding, welding yemotokari yekuchengetedza gasi jenareta. Laser kucheka kwezvikamu muyedzo uye diki batch yekugadzira nhanho yemotokari, uye welding yemabhatiri emotokari dzemagetsi.

9. Simba rekuvhenekera zvinhu zvekuvaka indasitiri

Laser processing inoshandiswa zvakanyanya mukugadzira laser solar cell: senge solar silicon wafer laser scribing yekucheka, solar mvura hita inopisa conduction plate welding. Laser processing, senzira yezvakatipoteredza uye inobudirira yekugadzirisa nzira, ichashandiswa zvakanyanya mune ramangwana.

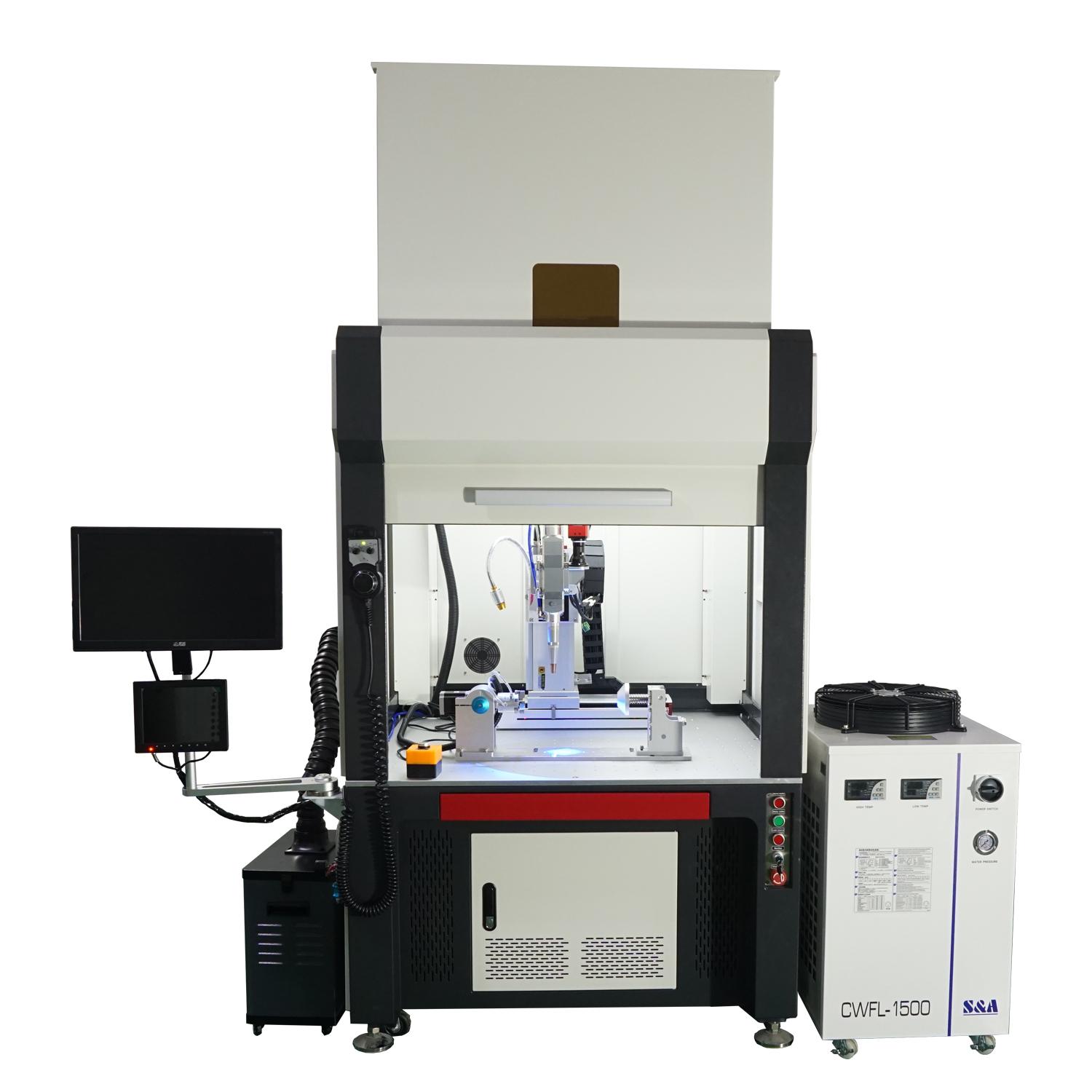

2.Chii chinonzi Platform otomatiki laser welding muchina?

Platform otomatiki laser welding muchina ndeye otomatiki welding muchina unoshandisa yakakwira-simba laser pulses kudziya munzvimbo munzvimbo diki. Simba reiyo laser radiation rinoparadzirwa kuburikidza nekupisa conduction kusvika mukati mechinhu uye zvinhu zvinonyungudutswa kuita dziva rakanyungudutswa. Inonyanya kushandiswa kugadzira zvinhu zvakatetepa-madziro uye mativi echokwadi, uye inokwanisa kuona magetsi welding, butt welding, lap welding, seal welding, etc. Iine maficha ediki weld wide, fast welding speed, high welding quality, kwete. porosity, kutonga kwakaringana, kurongeka kwepamusoro, uye nyore otomatiki.

3.Chii chinonzi handheld laser welding machine?

Sezvinoreva zita, manyorero laser welding muchina imhando yewelding michina inoda mashandiro emaoko. Iyi welding midziyo inogona kuita laser welding pane yakareba uye yakakura workpieces. Kana welding, kupisa kwakakanganiswa nzvimbo idiki uye haikonzeri deformation, blackening uye mavanga kumashure kweworkpiece. Kudzika kwemoto kwakakura, kusungirirwa kwakasimba, kunyunguduka kwakakwana, uye hapana kuora mwoyo mumvura yakanyunguduka apo kuratidzwa kwezvinhu zvakanyungudutswa kunosangana ne substrate.

4.Ndeipi musiyano pakati pe otomatiki Laser welding muchina uye handheld laser welding muchina?

Otomatiki laser welding michina inokwenenzverwa zvinoenderana neyakagadzikwa chirongwa mushure mekumisikidzwa musoftware; manual Laser welding machines, inozivikanwawo sekuti spot welding, inoshandiswa nevashandisi pavanenge vachishandisa laser welding michina kuburikidza nekukwidziridzwa kwepamusoro kuchidzitiro.

Visual spot welding inoitwa nemaoko uye inowanzo gadzirwa nevagadziri vemidziyo yelaser kuti isangane nezvinodiwa nemushandisi. Vagadziri vashoma vane stock zvinhu. Kana zvinhu zvestock zviripo, zvinopihwa kumushandisi se prototype kana proofing referensi. Zvinotonyanya kukosha, simba uye maficha emidziyo yewelding anotemerwa nekubvunzana nemushandisi, uye isu tinofanirawo kupa mushandisi chigadzirwa chemidziyo inodhura zvichienderana nemutengo wekutenga. Muchiitiko chipi zviri nani kushandisa manual laser welding muchina, uchienzaniswa neakazara automated laser welding muchina, kwete chete mutengo wekutenga wakakwira, asi mutengo wekugadzirisa zvakare wakanyanya kukwirira. Iyo yakanyanya kururamisa chimwe chinhu ndiyo inonyanya kukosha iyo yekuchengetedza uye zvakasikwa iyo yakakwirira mutengo. Uye zvakare, zvizere otomatiki laser welding inonyanya kutarisisa pane CNC otomatiki yepuratifomu yebasa, inoda kushanda kwepamusoro uye kuita kwakasiyana-siyana kwepuratifomu yebasa, asi mukuita, iyi haisi panacea, uye akawanda anochinja zvigadzirwa zvakasiyana hazvigone kushandiswa, izvo. inodzikamisa basa reotomatiki laser welding muchina. Nhasi, isu tinotarisa pamanyorero laser welding muchina, saka bhuku rekushandisa rinogadzirisa matambudziko ari pamusoro. Basa rayo rekushongedza ndere kuita welding operation ne handheld laser welding joint nemakona akasiyana ekudzora, saka inogona kunzi isiri-custom laser midziyo yekuchinjika kune welding yezvimiro zvakawanda uye makona ezvigadzirwa. Chero bedzi simba racho rakareba zvakakwana, rinogona kuchinjika kune welding yezvigadzirwa zvakawanda

Iko kugadzirwa kwemanyorero laser welding michina zvirokwazvo yakadzikira pane iyo yeakazara otomatiki michina. Nekudaro, kune decentralized processing kana isiri-hombe-chikero kugadzirisa uye welding yezvidyarwa zvekugadzira, manual laser welding inonyanya kubatsira. Hapana chikonzero chekugadzirisa tafura yewelding uye kudzivirira dambudziko renzvimbo huru yepasi. Pamusoro pezvo, mashopu madiki anopinza zvigadzirwa zvakasiyana siyana zvine maumbirwo asina kujairika, saka manual laser welding inogona kuzadzisa zvizere zvinodiwa zvekugadzira kwakadaro uye ine yakanaka kuchinjika.

Manual laser welding pasina chaiyo welding tafura, yakaderera kushandiswa kwezvinhu zvinodyiwa uye yakaderera kugadzirisa mutengo wemidziyo. Kazhinji kutaura, isu tinofanirwa kuchengetedza mamwe mabhenji ebasa, nepo manual laser michina inogona kupedzisa oparesheni chero yakashongedzerwa neanotakurika laser welding majoini. Zviri nyore kutsiva, mutengo wakaderera wekutsiva zvikamu. Kana iwe usingazivi nzira yekuvatsiva nayo, unogona kuvapa kumugadziri kuti agadzirise zvakananga pasina kunetseka nezvekutumira.

Musiyano uripo pakati peotomatiki laser welding michina uye manual laser welding michina yakagovaniswa pano. Vanhu vazhinji vanogona kufunga kuti otomatiki laser welder iri nani nekuti inongozviitira, asi chokwadi ndechekuti mhando mbiri dzemidziyo inoshandiswa kune zvakasiyana uye imwe neimwe ine zvayakanakira. Mukuita sarudzo, isu tinodawo kusarudza iyo chaiyo laser welding michina yekugadzira yedu zvinoenderana nezvatinoda chaizvo.

Nguva yekutumira: Feb-01-2023