Semutakuri wezvimwe zvikamu zvemotokari, iyo tekinoroji yekugadzira yemuviri wemotokari inosarudza zvakananga huwandu hwese hwekugadzira hwemotokari. Mukuita kwekugadzira auto body, welding inzira yakakosha yekugadzira. Iwo matekinoroji ekugadzira pari zvino anoshandiswa kugadzira auto body welding anonyanya kusanganisira kuramba nzvimbo welding, yakanyungudutswa inert gasi yakadzivirirwa welding (MIG welding) uye yakanyungudutswa inoshanda gasi yakadzivirirwa arc welding (MAG welding) pamwe nelaser welding.

Seyepamusoro welding tekinoroji ine optical-mechanicha yekubatanidza, laser welding tekinoroji ine zvakanakira yakakwira simba density, kukurumidza welding kumhanya, yakaderera welding kusagadzikana uye deformation, uye yakanaka kuchinjika zvichienzaniswa neyechinyakare auto body welding tekinoroji.

Chimiro chemuviri wemotokari chakaoma, uye nhengo dzemuviri dzakanyanya kutetepa-madziro uye dzakakombama zvikamu. Auto body welding inotarisana nezvinetso zvewelding senge kusiyanisa kwezvinhu zvemuviri, kusiyanisa ukobvu hwenhengo dzemuviri, akasiyana welding trajectories uye majoini mafomu. Uye zvakare, mota welding yemuviri ine zvakakwirira zvinodikanwa pane welding mhando uye welding kunyatsoita.

Zvichienderana neakakodzera welding process paramita, laser welding inogona kuve yakakwira kuneta simba uye kukanganisa kuomarara kweakakosha auto nhengo dzemuviri kana welding, nekudaro kuve nechokwadi chemhando uye sevhisi yehupenyu hwekubatisa muviri. Laser welding tekinoroji inogona kuchinjika kune welding yenhengo dzemuviri dzeauto dzine akasiyana mafomu akabatana, ukobvu hwakasiyana uye akasiyana emhando yemhando, achizadzisa kudiwa kwekuchinjika mukugadzira auto body. Naizvozvo, laser welding tekinoroji yakakosha tekinoroji nzira yekuwana yakakwirira-mhando yekusimudzira indasitiri yemotokari.

Laser welding process yemiviri yemotokari

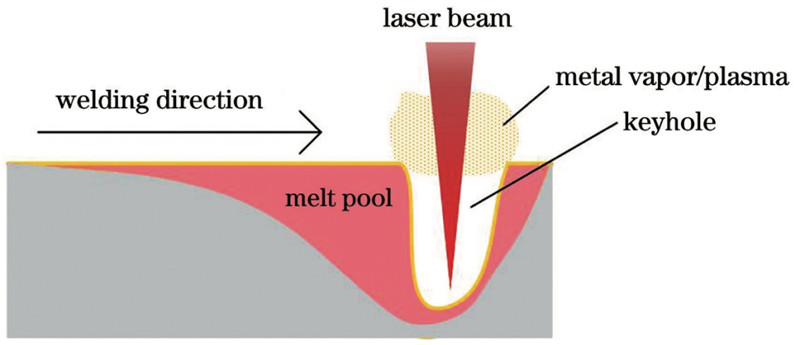

Laser yakadzika fusion welding process musimboti: Kana iyo laser simba density yasvika pane imwe nhanho, iyo yepasi pevhu inoputika, nekudaro ichigadzira kiyi hole. Kana iyo simbi mhute yekumanikidza mukati megomba inosvika pakusimba kuenzana neiyo static kudzvanywa uye kusimba kwepasi kwemvura yakatenderedza, laser inogona kupenya kuburikidza nekiyi kusvika pasi pegomba, uye nekufamba kwelaser beam, inoenderera weld iri. akaumbwa. Mune laser yakadzika fusion welding process, hapana chikonzero chekuwedzera yekubatsira flux kana filler kuti weld iyo workpiece yega zvinhu kuita imwe.

Iyo weld seam inowanikwa nelaser yakadzika fusion welding kazhinji yakatsetseka uye yakatwasuka ine diki deformation, iyo inobatsira kuvandudza iko kwekugadzira kwemuviri wemotokari. Iko kusimba kwekusimba kweweld kwakakwira, izvo zvinove nechokwadi chemhando yewelding yemuviri wemotokari. Iyo welding yekumhanyisa inokurumidza, iyo inobatsira kuvandudza kugona kwekugadzira welding.

Mune auto body welding process, kushandiswa kwelaser deep fusion welding process kunogona kuderedza zvakanyanya huwandu hwezvikamu, molds uye welding tooling, nokudaro kuderedza huremu hwemuviri uye mutengo wekugadzira. Nekudaro, iyo laser yakadzika fusion welding process haina kushivirira kune gaka regungano rezvikamu zvinosungirirwa, uye gaka regungano rinoda kudzorwa pakati pe0.05 ne2 mm. Kana mukaha wegungano wakakurisa, zvirema zvewelding senge porosity zvichaitika.

Tsvagiridzo yazvino inoratidza kuti mu auto body welding yechinhu chimwe chete, nekugadzirisa maparamendi e laser yakadzika-fusion welding, zvinokwanisika kuwana weld ine yakanaka kuumbwa kwepasi, kushomeka kwemukati kukanganisa uye yakanakisa mechaniki zvinhu. Iyo yakanakisa mechanic zvimiro zve weld inogona kusangana nezvinodiwa zvekushandisa zve auto body welded zvikamu. Nekudaro, mune auto body welding, aluminium alloy-simbi semumiriri weiyo heterogeneous simbi laser yakadzika fusion welding process haina kukura, kunyangwe nekuwedzera yekuchinja layer inogona kuwana yakanakisa kuita kweiyo weld, asi akasiyana ekuchinja layer zvinhu pa IMC layer pesvedzero meshini uye mhedzisiro yayo pane diki chimiro che weld meshini haina kujeka, inoda imwe yakadzama kudzidza.

Auto Body Laser Wire Kuzadza Welding Maitiro

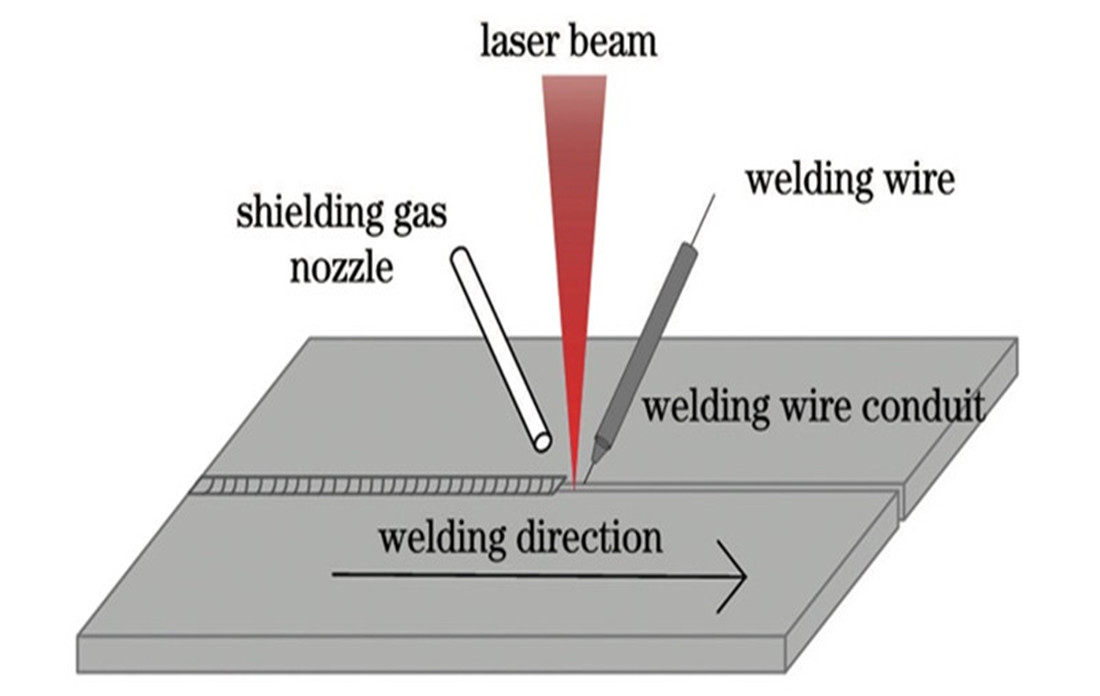

Iyo laser filler welding process yakavakirwa pane inotevera musimboti: Iyo welded joint inoumbwa nekutanga-kuzadza iyo weld newaya chaiyo kana nekudyisa waya panguva imwe chete panguva ye laser welding process. Izvi zvakaenzana nekudyisa ingangoita homogeneous huwandu hwewaya zvinhu muweld pool panguva yelaser deep fusion welding. Dhiagiramu iri pazasi inoratidza iyo laser filler welding process.

Kuenzaniswa nelaser yakadzika fusion welding, laser filler welding ine mabhenefiti maviri mu auto body welding: chekutanga, inogona kuvandudza zvakanyanya kushivirira kwegungano gaka pakati peauto nhengo dzemuviri kuti dzive welded uye kugadzirisa dambudziko repamusoro bevel gap chinodiwa kune laser yakadzika fusion welding. ; chechipiri, inogona kuvandudza kugoverwa kwetishu munzvimbo ye weld nekushandisa waya dzine akasiyana ezvinyorwa zvemukati, uyezve kugadzirisa weld performance.

Mukuita kwekugadzira otomatiki muviri, laser filler welding process inonyanya kushandiswa kugadzira aluminium alloy uye simbi nhengo dzemuviri. Kunyanya mukugadzirisa kwealuminium alloy zvikamu zveauto body, kushushikana kwepasi kwedziva rakanyungudutswa kudiki, izvo zvinogona kutungamira mukudonha kwedziva rakanyungudutswa, nepo laser filler welding process inogona kugadzirisa zvirinani dambudziko rekudonha kwedziva. kuburikidza nekunyunguduka kwewaya mune laser welding process.

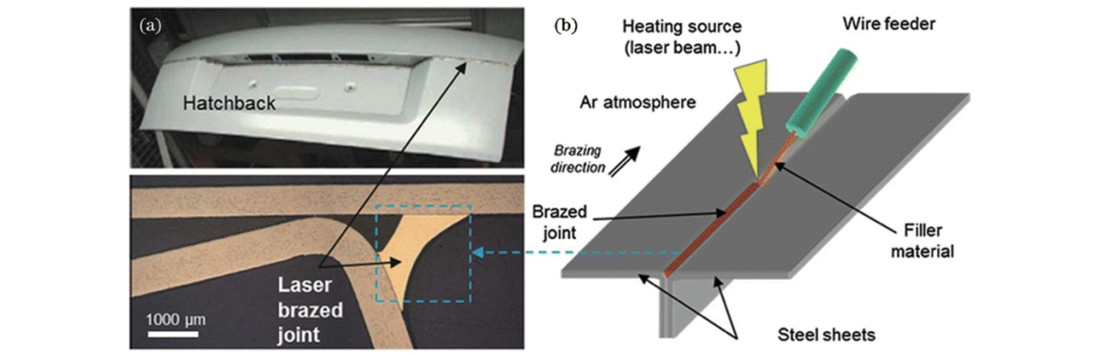

Automotive body laser brazing process

Iyo laser brazing process yakavakirwa pane inotevera musimboti: Uchishandisa laser senge sosi yekupisa, iyo laser danda inotariswa uye yakavhenekerwa pamusoro pewaya, waya inonyungudika, waya yakanyunguduka inodonha pasi uye inozadza workpiece kuti isimbiswe, uye metallurgical migumisiro yakadai sekunyunguduka uye kupararira kunoitika pakati pekugadzirisa zvinhu uye workpiece, nokudaro vachibatanidza workpiece. Kusiyana nelaser filler welding process, iyo laser brazing process inonyungudutsa waya chete kwete iyo workpiece kuti isimbiswe. Laser brazing ine yakanaka welding kugadzikana, asi kusimba kwekusimba kweinokonzeresa weld yakaderera. Mufananidzo 3 unoratidza kushandiswa kwelaser brazing process mune yemotokari mikwende yekamuri yekuvharira welding

Mukuita kweauto body welding, laser brazing process inonyanya kushandiswa kubatanidza nhengo dzemuviri dzisingadi kusimba kwekubatana, senge welding pakati pechivharo chepamusoro uye padivi zvakatenderedza, welding pakati pepamusoro nechepazasi chikamu chemukwende. compartment cover, etc. The top cover of VW, Audi and other medium and high-end models vese vari kushandisa laser brazing process.

Hurema hukuru mulaser brazed majoini emitumbi yemotokari dzinosanganisira kugeda, porosity, weld deformation, nezvimwewo, uye hurema hunogona kudzvanywa zvakanyanya nekugadzirisa maparamendi uye kushandisa akawanda-yakatarisana laser brazing process.

Automotive body laser-arc composite welding process

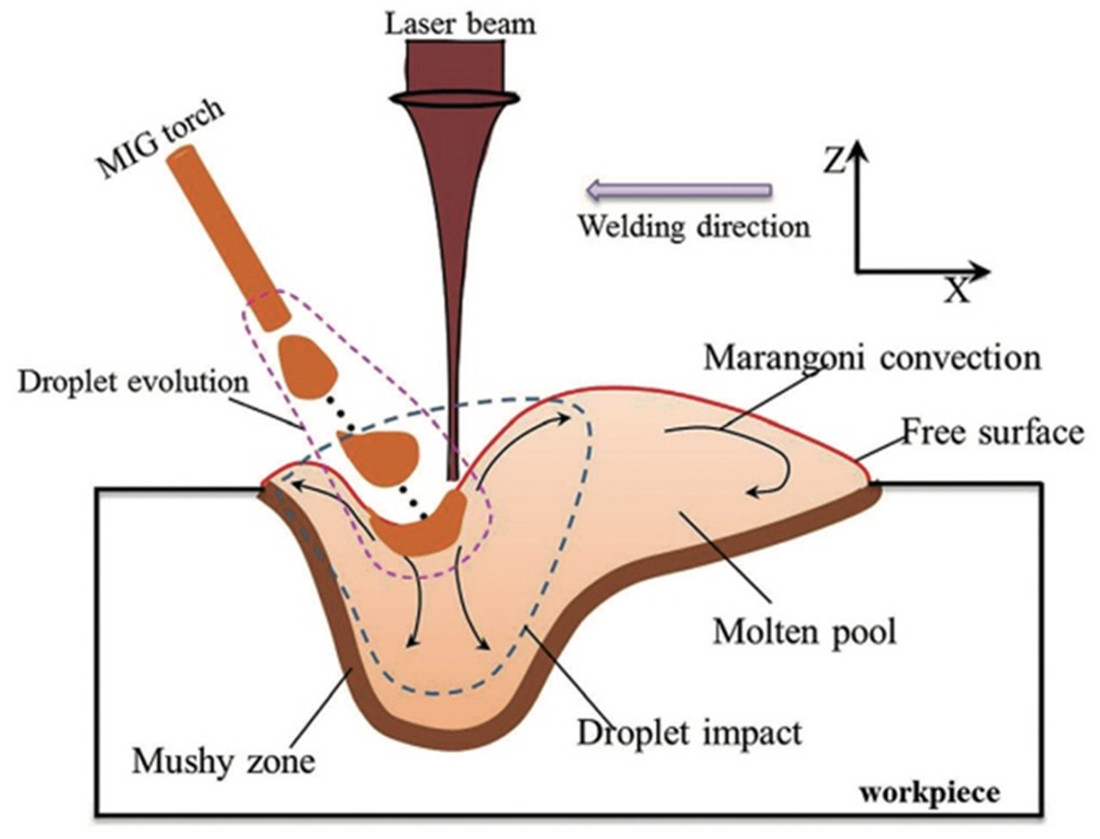

Nheyo yelaser-arc composite welding process ndeiyi inotevera: maviri ekupisa masosi, laser uye arc, anoshandiswa kuita panguva imwe chete pamusoro peiyo workpiece kuti isungirwe, uye workpiece inonyungudutswa uye yakasimbiswa kuita weld seam. Dhiagiramu iri pazasi inoratidza iyo laser-arc welding process.

Laser-arc composite welding inosanganisa zvakanakira laser welding uye arc welding: kutanga, pasi pekuita kwehuviri kupisa masosi, kumhanya kwewelding kunogona kuwedzerwa, kupinza kwekupisa kunova kudiki, iyo weld deformation idiki, kuchengetedza hunhu hwelaser welding. ; chechipiri, kugona bhiriji kurinani, kushivirira kwegungano kwakakura; chechitatu, kukurumidza kusimba kwedziva rakanyungudutswa kunowedzera kunonoka, izvo zvinobatsira pakubviswa kwepores, kuputika uye zvimwe zvinokanganisa welding, kuvandudza kurongeka uye kushanda kwenzvimbo inopisa-inopisa yechina, nekuda kwearc, inokwanisa weld. zvinhu zvine high reflectivity uye high thermal conductivity, ine hupamhi hwakawanda hwezvinhu zvakashandiswa.

Mukugadzira auto body process, laser - arc composite welding process inonyanya kuchinjisa muviri aluminium alloy zvikamu uye aluminium alloy - simbi dzakasiyana simbi, kune gaka regungano rezvikamu zvakakura zvewelding, senge gonhi remotokari chikamu chenzvimbo iyo welding, izvi zvinodaro nekuti gaka regungano rinobatsira kune laser - arc composite welding bridging performance. Uye zvakare, iyo laser-MIG arc composite welding tekinoroji inoiswawo kune padivi pedenga danda chinzvimbo chemuviri weAudi.

Mune auto body welding process, laser-arc composite welding ine mukana wekushivirira kwakakura kana zvichienzaniswa neaser welding imwe chete, zvisinei, laser-arc composite welding inoda kutariswa kwakadzama kwechinzvimbo chehukama chelaser uye arc, laser welding paramita, arc. parameters nezvimwe zvinhu. Kupisa uye hukuru hwekufambisa maitiro eiyo laser-arc welding process yakaoma, kunyanya iyo simba regulation yeheterogeneous material welding uye magadzirirwo eIMC ukobvu uye kudzorwa kwetishu haisati yanyatsojeka uye inoda kumwe kusimbiswa kwetsvagiridzo.

Zvimwe zvemotokari muviri laser welding maitiro

Laser yakadzika fusion welding, laser filler welding, laser brazing uye laser-arc composite welding uye mamwe maitirwo ewelding ane dzidziso yakakura uye yakawanda yeanoshanda maapplication. Sezvo izvo indasitiri yemotokari zvinodikanwa zvemuviri welding kushanda zvakanaka zvichiwedzera uye kudiwa kwewelding yezvinhu zvakasiyana mukugadzira huremu hunowedzera, laser spot welding, laser oscillation welding, multi-laser beam welding uye laser flight welding zvawana kutariswa.

Laser nzvimbo welding process

Laser spot welding ndeye advanced laser welding tekinoroji ine yakatanhamara mabhenefiti ekukurumidza welding kumhanya uye yakakwirira welding chaiyo. Nheyo yakakosha yelaser spot welding ndeyekutarisa danda relaser pane imwe nzvimbo inosungirirwa, kuitira kuti simbi panguva iyoyo inyunguduke ipapo, uye nekugadzirisa laser density kuti iwane thermal conduction welding kana yakadzika fusion welding effect, kana laser beam yamira kushanda, iyo simbi yemvura inoyerera, inoomesa uye inoita mubatanidzwa.

Pane nzira mbiri huru dzelaser spot welding: pulsed laser spot welding uye inoenderera mberi laser spot welding. Iyo laser beam in pulsed laser spot welding ine yakakwira simba repamusoro, asi nguva yekuita ipfupi, uye inowanzo shandiswa kubatanidza simbi dzakareruka senge magnesium alloys uye aruminiyamu alloys. Mukuenderera mberi laser spot welding, iyo laser beam ine yakakwira avhareji simba uye yakareba laser chiitiko nguva, uye inonyanya kushandiswa kupinza simbi.

Mu auto body welding, zvichienzaniswa neresistance spot welding, laser spot welding ine zvakanakira zvisiri zvekubatana uye zvakazvigadzira wega nzvimbo welding trajectory, iyo inogona kusangana nezvinodiwa zvemhando yepamusoro welding pasi pemagapu akasiyana emidziyo yemotokari.

Laser oscillation welding process

Laser oscillation welding ndiyo itsva laser welding tekinoroji yakatsanangurwa mumakore achangopfuura uye yakagamuchira kutariswa kwakapararira. Nheyo yeiyi tekinoroji ndeyekuwana kukurumidza, kurongeka uye kudiki oscillation yelaser beam nekubatanidza girazi rinotenderedza mumusoro welaser welding, nekudaro uchiwana mhedzisiro yekuzunguza danda uchienda kumberi panguva yekupisa laser.

Iwo makuru oscillation trajectories mune laser oscillation welding process anosanganisira: transverse oscillation, longitudinal oscillation, denderedzwa oscillation uye kusingaperi oscillation. Iyo laser oscillation welding process ine mabhenefiti akakosha mu auto body welding, sezvo kuyerera kwechidziva chakanyunguduka kuchichinjika zvakanyanya neiyo oscillation yelaser beam, saka maitiro anogona kubvisa hurema husina kusanganiswa, kuwana kunatswa kwezviyo uye kudzvanya porosity mukupisa. iwowo auto body material, uye gadzirisa matambudziko ekusakwana kusanganiswa kwezvinhu zvakasiyana uye kushomeka kwemuchina zvivakwa zve weld seam mukukwenenzverwa kwezvinhu zvakasiyana auto body.

Multi-laser beam welding process

Parizvino, fiber lasers inogona kushandiswa kupatsanura imwe laser danda kuita akawanda laser matanda uchishandisa danda kupatsanura module yakaiswa mu welding musoro. Multi-laser beam welding yakaenzana nekushandisa akawanda kupisa masosi muwelding process. Nekugadzirisa kugoverwa kwesimba kwedanda, matanda akasiyana-siyana anogona kuita mabasa akasiyana-siyana, akadai se: danda rine simba guru guru ndiro danda guru, rinotarisira kunyunguduka kwakadzika; iyo sub-beam ine yakaderera simba density inogona kuchenesa uye preheat iyo yepasi yepamusoro uye kuwedzera kutorwa kwelaser beam simba nezvinhu.

Iyo yakawanda-laser beam welding process inogona kuvandudza maitiro evaporation ye zinc vapor uye hunhu hunosimba hwechidziva chakanyunguduka panguva yekuputirwa kwemarata ane galvanized simbi, kunatsiridza dambudziko rekuparadzira uye kuwedzera kusimba kwekusimba kweiyo weld seam.

Laser ndege welding process

Laser ndege welding tekinoroji ndiyo itsva laser welding tekinoroji ine yakakwira welding kunyatsoshanda uye yakazvimirira dhizaini yewelding trajectory. Nheyo yakakosha yelaser flight welding ndeyekuti kana laser beam ikaitika paX uye Y magirazi egirazi rekuvheneka, kona yegirazi inodzorwa kuburikidza nekuzvimiririra hurongwa kuti uwane kutsauka kwelaser beam chero kona.

Sechinyakare, laser welding yeauto body inonyanya kutsamira pane welding robhoti kutyaira iyo laser welding musoro wesynchronous motion kuti uwane iyo welding mhedzisiro. Zvisinei, kudzokororwa kunodzokororwa kwerobhoti yewelding kunoderedza zvakanyanya kushanda kwe auto body welding nekuda kwenhamba huru yewelds uye kureba kwewelds. Kusiyana neizvi, laser flight welding inogona kuwanikwa mukati meimwe renji nekungogadzirisa kona yereflector. Naizvozvo, laser ndege welding tekinoroji inogona kuvandudza zvakanyanya kushanda kwewelding uye ine tarisiro yakakura yekushandisa.

Summary

Nekuvandudzwa kweindasitiri yemotokari, ramangwana remuviri welding tekinoroji richaramba richikura mune ese ari maviri ekuita welding uye nehungwaru tekinoroji.

Auto body, kunyanya iyo nyowani simba mota muviri, iri kusimukira munzira yekureruka huremu. Lightweight alloys, composite zvinhu uye heterogeneous zvinhu zvichave zvakanyanya kushandiswa mu auto body, yakajairwa laser welding process inonetsa kuzadzisa ayo welding zvinodiwa, saka yemhando yepamusoro uye inoshanda welding process inozoita ramangwana rekusimudzira maitiro.

Mumakore achangopfuura, iri kusimukira laser welding process, senge laser swing welding, multi-laser beam welding, laser flight welding, nezvimwewo, yanga iri mumhando yewelding uye kugona kwewelding yekutanga dzidziso yekutsvagisa uye maitiro ekuongorora. Ramangwana rinoda kuve riri kubuda laser welding process uye auto body lightweight zvinhu, heterogeneous zvinhu welding uye zvimwe zviitiko zvakanyatsobatanidzwa, iyo laser beam swing trajectory dhizaini, akawanda-laser beam simba rekuita maitiro uye ndege welding budiriro uye zvimwe zvinhu zve- tsvakiridzo yakadzama yekuongorora yakakura lightweight auto body welding process.

Auto body laser welding tekinoroji iri kubatanidzwa zvakanyanya nehungwaru tekinoroji, real-time sensing ye auto body laser welding mamiriro uye mhinduro yekutonga kwema process paramita ine basa rakasimba mumhando yewelding. Iyo yazvino yakangwara laser welding tekinoroji inonyanya kushandiswa pre-welding trajectory kuronga uye yekutevera uye post-welding mhando yekuongorora. Tsvagiridzo yemukati neyekunze mukuona kwekuremerwa kwewelding uye inogadzirisa gadziriso yemaparamendi ichiri muhucheche, uye laser welding process parameters adaptive control tekinoroji haisati yashandiswa mukugadzira muviri wemotokari.

Naizvozvo, pakushandiswa kwelaser welding tekinoroji mune auto body welding process maitiro, ramangwana rinofanirwa kuvandudzwa neakakwira-sensor core laser welding intelligent sensing system uye yakakwirira-yepamusoro-chaiyo welding robhoti yekudzora system kuona kuti iyo laser welding. yakangwara tekinoroji munguva chaiyo uye kurongeka kwechimwe nechimwe chinongedzo, kuburikidza ne "pre-welding trajectory planning - welding parameters adaptive control post-welding quality online Inspection" link, kuti ive nechokwadi chepamusoro uye kushanda zvakanaka.

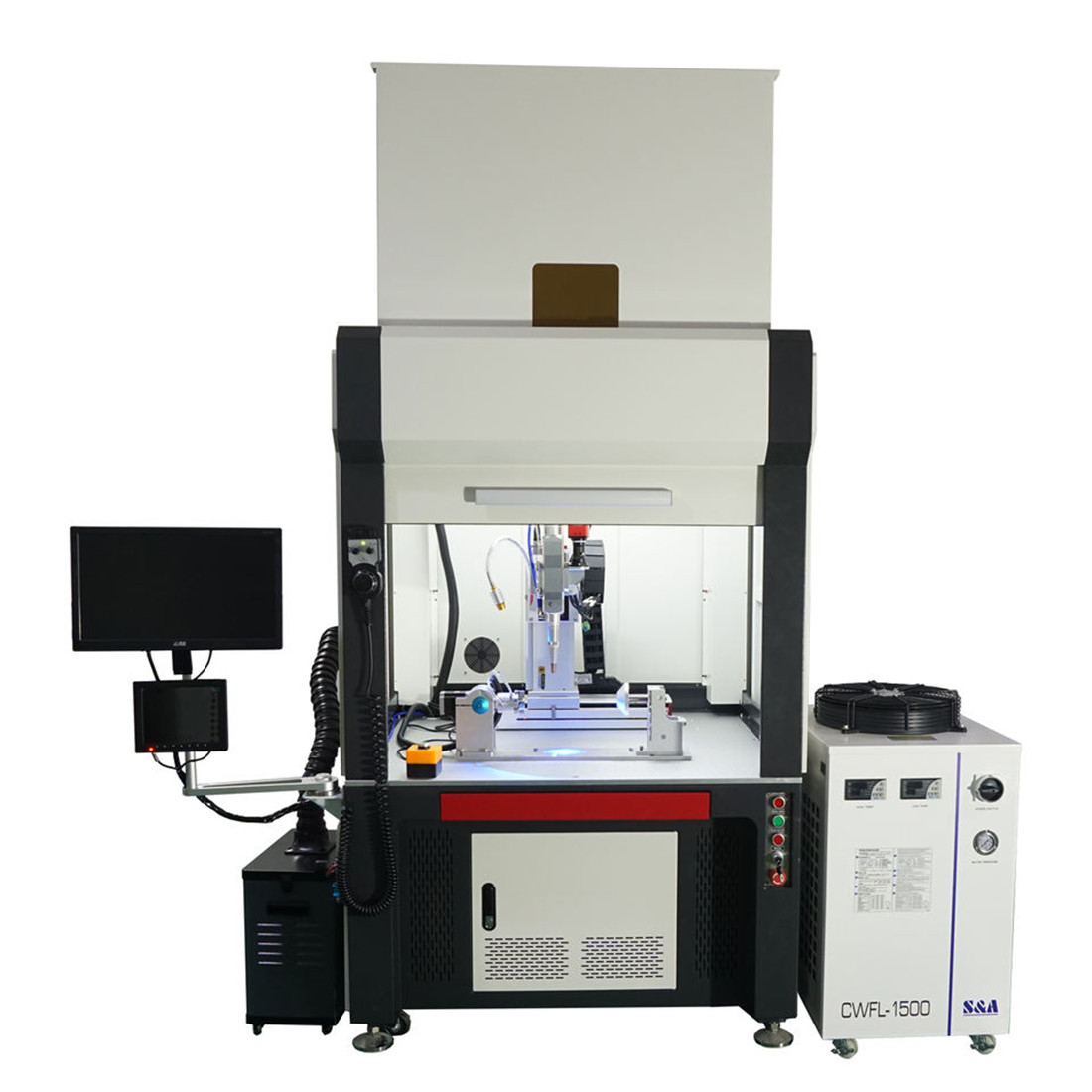

Maven laser otomatiki kambani inotarisisa indasitiri yelaser kwemakore gumi nemana, isu tine hunyanzvi mulaser welding, tine marobhoti ruoko laser welding muchina, Tafura Automatic Laser Welding muchina, Handheld Laser welding muchina, mukuwedzera, isu zvakare tine laser welding muchina, laser yekucheka muchina. uye laser yekumaka yekumisikidza muchina, isu tine akawanda laser welding mhinduro makesi, kana uchifarira unogona kugara uchitibata.

Nguva yekutumira: Zvita-09-2022