Mumakore achangopfuura, nekuda kwekukurumidza kusimudzira kweindasitiri yesimba idzva, laser welding yakakurumidza kupinda muindasitiri yesimba idzva nekuda kwekukurumidza uye kwakagadzikana zvakanakira. Pakati pavo, laser welding michina inoverengera chikamu chepamusoro chekushandisa muindasitiri itsva yesimba.

Laser weldingyakakurumidza kuve sarudzo yekutanga mumafambiro ese ehupenyu nekuda kwekumhanya kwayo, kudzika kukuru, uye kudiki deformation. Kubva pane machira emoto kusvika kumabutt welds, kuvaka-up uye seal welds,laser weldinginopa kunyatsojeka uye kutonga kusingaenzaniswi. Inoita basa rakakosha mukugadzirwa kwemaindasitiri nekugadzira, kusanganisira indasitiri yemauto, kurapwa, aerospace, 3C auto zvikamu, mechaniki sheet simbi, simba idzva uye mamwe maindasitiri.

Kuenzaniswa nehumwe tekinoroji welding, laser welding ine yakasarudzika mabhenefiti uye yakashata.

Advantage:

1. Kukurumidza kukurumidza, kudzika kukuru uye deformation duku.

2. Welding inogona kuitwa pane yakajairika tembiricha kana pasi akakosha mamiriro, uye welding midziyo iri nyore. Semuenzaniso, danda relaser harinyunguruke mumunda wemagetsi. MaLaser anogona weld mune vacuum, mhepo kana imwe gasi nharaunda, uye anogona weld zvinhu zviri kuburikidza negirazi kana pachena kune laser beam.

3. Inogona weld refractory zvinhu zvakadai setitanium uye quartz, uye inogonawo weld zvinhu zvakasiyana nemigumisiro yakanaka.

4. Mushure mokunge laser inotarisa, simba remagetsi rakakwirira. Chiyero chechikamu chinogona kusvika pa5: 1, uye inogona kusvika kusvika 10: 1 kana welding yakakwira-simba zvishandiso.

5. Micro welding inogona kuitwa. Mushure mekunge danda relaser ratariswa, nzvimbo diki inogona kuwanikwa uye inogona kuiswa nenzira kwayo. Inogona kuiswa kumusangano uye welding yezvidiki uye zvidiki workpieces kuti uwane otomatiki misa kugadzirwa.

6. Inogona weld yakaoma-kusvika-nzvimbo uye kuita isingabatanidzi kure-kure welding, nekushanduka kukuru. Kunyanya mumakore achangopfuura, YAG laser processing tekinoroji yakatora optical fiber transmission tekinoroji, iyo yakagonesa laser welding tekinoroji kuti isimudzirwe zvakanyanya uye ishandiswe.

7. Laser beam iri nyore kupatsanurwa munguva nenzvimbo, uye matanda akawanda anogona kugadziriswa munzvimbo dzakawanda panguva imwe chete, achipa mamiriro ekuwedzera kwakaringana welding.

Kukanganisa:

1. Iko kurongeka kwegungano kwe workpiece kunodiwa kuti ive yakakwirira, uye nzvimbo yedanda pane workpiece haigoni kukanganiswa zvakanyanya. Izvi zvinodaro nekuti iyo laser nzvimbo saizi mushure mekutarisa idiki uye weld musono wakamanikana, zvichiita kuti zviome kuwedzera filler simbi zvinhu. Kana iko kurongeka kwegungano kweiyo workpiece kana kurongeka kweiyo danda kusingaenderane nezvinodiwa, welding defects inowanzoitika.

2. Mutengo we lasers uye ane hukama masisitimu akakwira, uye iyo imwe-nguva yekudyara yakakura.

Common laser welding defectsmukugadzira lithium bhatiri

1. Welding porosity

Common kukanganisa mukatilaser weldingari pores. Dziva rakanyungudutswa remoto wakadzika uye nhete. Munguva ye laser welding process, nitrogen inopinda mudziva rakanyungudutswa kubva kunze. Munguva yekutonhodza nekuomesa simbi, kunyungudika kwenitrogen kunodzikira nekudzikira kwetembiricha. Kana iyo yakanyungudutswa dziva simbi inotonhora kuti itange kupenya, , iyo solubility ichadonha zvakanyanya uye kamwe kamwe. Panguva ino, huwandu hukuru hwegasi huchanaya kuita mabubbles. Kana iyo inoyangarara yekumhanya yemabhuru ishoma pane simbi crystallization kumhanya, pores inogadzirwa.

Mumaapplication ari muindasitiri yebhatiri yelithium, tinowanzoona kuti pores inonyanya kuitika panguva yewelding yeyakanaka electrode, asi kashoma kuitika panguva yekunyungudutswa kweiyo negative electrode. Izvi zvinodaro nekuti iyo yakanaka electrode inogadzirwa nealuminium uye iyo yakaipa electrode yakagadzirwa nemhangura. Munguva yewelding, iyo aluminium yemvura iri pamusoro yakanyunguduka mukati megasi remukati risati rafashukira zvachose, kudzivirira gasi kuti risapfachukire uye kugadzira makomba makuru nemadiki. Small stomata.

Mukuwedzera kune zvikonzero zvepores zvataurwa pamusoro apa, pores inosanganisirawo kunze kwemhepo, unyoro, mafuta epamusoro, nezvimwewo. Uyezve, kutungamira uye kona ye nitrogen inoputika ichakanganisawo kuumbwa kwepores.

Nezve nzira yekudzikisa kuitika kwe welding pores?

Kutanga, pamberiwelding, mavara emafuta uye tsvina pamusoro pezvinhu zvinopinda zvinoda kucheneswa nenguva; mukugadzirwa kwemabhatiri e-lithium, kuongorora kwezvinhu zvinopinda chinhu chakakosha maitiro.

Chechipiri, iyo inodzivirira gasi kuyerera kunofanirwa kugadziridzwa zvinoenderana nezvinhu zvakaita sewelding kumhanya, simba, chinzvimbo, nezvimwe, uye haifanirwe kunge yakakura kana kudiki. Iyo yekudzivirira yejasi kumanikidza inofanirwa kugadziridzwa zvinoenderana nezvinhu zvakaita selaser simba uye chinzvimbo chekutarisa, uye haifanirwe kunge yakanyanya kukwirira kana kuderera. Chimiro chevhavha yevhavha inodzivirira inofanira kuchinjwa maererano nechimiro, kutungamira uye zvimwe zvinhu zve weld kuitira kuti chivharo chekudzivirira chikwanise kuvhara zvakaenzana nzvimbo yemoto.

Chechitatu, dzora tembiricha, mwando uye guruva mumhepo muwekishopu. The ambient tembiricha uye mwando kuchakanganisa mwando pamusoro pepamusoro pe substrate uye gasi anodzivirira, izvo zvichazokanganisa chizvarwa uye kupukunyuka kwemhute yemvura mudziva rakanyungudutswa. Kana iyo ambient tembiricha uye hunyoro zvakanyanyisa, pachava nekunyorova kwakawanda pamusoro peiyo substrate uye gasi rinodzivirira, rinogadzira huwandu hukuru hwemhute yemvura, zvichikonzera pores. Kana iyo ambient tembiricha uye humidity yakanyanya kuderera, pachava nekunyorova kudiki pamusoro peiyo substrate uye mune inodzivirira gasi, kuderedza kugadzirwa kwemhute yemvura, nokudaro kuderedza pores; rega vashandi vemhando vaone kukosha kwechinangwa chekushisa, humidity uye guruva pachiteshi chemagetsi.

Chechina, iyo danda rekugezera nzira inoshandiswa kuderedza kana kubvisa pores mune laser yakadzika yekupinda welding. Nekuda kwekuwedzera kwekuzunungusa panguva yewelding, kudzoreredza kutenderera kwedanda kune weld seam kunokonzera kudzokororwa kudzokororwa kwechikamu che weld seam, iyo inorebesa nguva yekugara kwesimbi yemvura mudziva rekushongedza. Panguva imwecheteyo, kutsauka kwedanda kunowedzerawo kupinza kwekupisa pane imwe nzvimbo. Kudzika-kusvika-kufara kweyero ye weld kunoderedzwa, iyo inobatsira pakubuda kwemabhuru, nokudaro kubvisa pores. Kune rumwe rutivi, kuzununguka kwedanda kunokonzera kuti gomba duku rizungunuke zvakakodzera, iro rinogonawo kupa simba rinokurudzira rekudziva rekutsvaira, kuwedzera kutenderera uye kubvongodza kwechidziva chemoto, uye kuva nemigumisiro inobatsira pakubvisa pores.

Chechishanu, iyo pulse frequency, iyo pulse frequency inoreva huwandu hwemapurusi anoburitswa nelaser beam pane imwe unit nguva, iyo inozokanganisa kupisa kwekupisa uye kuunganidzwa kwekupisa mudziva rakanyungudutswa, uye zvobva zvakanganisa tembiricha yemunda uye kuyerera munda mune yakanyungudutswa. dziva. Kana pulse frequency yakawandisa, zvinozotungamira mukupisa kwakanyanya mudziva rakanyungudutswa, zvichiita kuti tembiricha yedziva yakanyungudutswa iwedzere zvakanyanya, ichiburitsa mhute yesimbi kana zvimwe zvinhu zvinoputika pakupisa kwakanyanya, zvichikonzera pores. Kana iyo pulse frequency yakanyanya kuderera, zvinotungamira mukusakwana kwekupisa kuunganidza mudziva rakanyungudutswa, zvichiita kuti tembiricha yedziva yakanyungudutswa kuve yakaderera, kuderedza kunyungudika uye kupukunyuka kwegasi, zvichikonzera pores. Kazhinji kutaura, iyo pulse frequency inofanirwa kusarudzwa mukati meiyo inonzwisisika renji zvichienderana ne substrate ukobvu uye laser simba, uye dzivirira kukwira zvakanyanya kana kuderera.

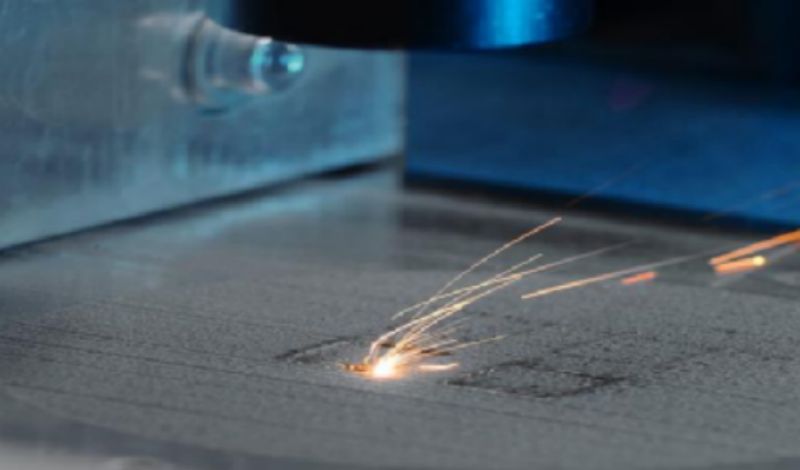

Welding maburi (laser welding)

2. Weld spatter

Iyo spatter inogadzirwa panguva yewelding process, laser welding ichakanganisa zvakanyanya kunaka kweiyo weld, uye ichasvibisa nekukuvadza lens. Kuitwa kwakawanda kwakafanana nekutevera: mushure mekunge laser welding yapera, akawanda masimbi masimbi anoonekwa pamusoro pechinhu kana workpiece uye anonamatira pamusoro pechinhu kana workpiece. Iyo yakanyanya intuitive kuita ndeyekuti kana welding mumodhi yegalvanometer, mushure menguva yekushandiswa kweinodzivirira lens yegalvanometer, pachava nemakomba akakora pamusoro, uye makomba aya anokonzerwa newelding spatter. Mushure menguva refu, zviri nyore kuvhara mwenje, uye pachava nematambudziko nemwenje welding, zvichikonzera nhevedzano yematambudziko akadai seakaputsika welding uye virtual welding.

Ndezvipi zvikonzero zvekupfachura?

Chekutanga, kuwanda kwesimba, kuwanda kwesimba guru, zviri nyore kugadzira spatter, uye spatter yakanangana nekuwanda kwesimba. Iri idambudziko rave nemakore zana. Kusvika pari zvino, indasitiri haina kukwanisa kugadzirisa dambudziko rekuputika, uye inogona kungotaura kuti yakaderedzwa zvishoma. Muindasitiri yelithium bhatiri, kupuruzira ndiyo honzeri huru yebhatiri pfupi, asi haina kukwanisa kugadzirisa iyo midzi. Mhedzisiro ye spatter pabhatiri inogona kuderedzwa chete kubva pakuona kwekudzivirira. Semuenzaniso, denderedzwa rekubvisa guruva zviteshi uye zvivharo zvekudzivirira zvinowedzerwa zvakatenderedza chikamu chewelding, uye mitsara yemapanga emhepo inowedzerwa mudenderedzwa kudzivirira kukanganisa kwe spatter kana kukuvadza bhatiri. Kuparadza nharaunda, zvigadzirwa uye zvikamu zvakatenderedza welding station zvinogona kunzi zvakapedza nzira.

Kana zviri zvekugadzirisa dambudziko re spatter, zvinogona kungotaurwa kuti kuderedza simba rekushongedza kunobatsira kuderedza spatter. Kuderedza kumhanya kwewelding kunogona kubatsirawo kana kupinda kusina kukwana. Asi mune mamwe maitiro akakosha zvinodiwa, haina mhedzisiro. Ndiwo maitiro akafanana, michina yakasiyana uye mabheti akasiyana ezvishandiso ane akasiyana zvachose welding mhedzisiro. Naizvozvo, pane mutemo usina kunyorwa muindasitiri yesimba idzva, imwe seti yewelding paramita kune imwe chidimbu chemidziyo.

Chechipiri, kana pamusoro pezvinhu zvakagadziridzwa kana workpiece isina kucheneswa, mavara emafuta kana zvinosvibisa zvinokonzeresa kuputika kwakakomba. Panguva ino, chinhu chiri nyore ndechekuchenesa pamusoro pezvinhu zvakagadziriswa.

3. High reflectivity of Laser welding

Kazhinji kutaura, kutarisisa kwepamusoro kunoreva chokwadi chekuti iyo yekugadziridza ine diki resistivity, nzvimbo yakati chechetere, uye yakaderera yekunyudza chiyero chepedyo-infrared lasers, iyo inotungamira kune yakakura yakawanda laser emission, uye nekuti mazhinji lasers anoshandiswa. yakatwasuka Nekuda kwechinhu kana diki diki yekurerekera, iyo laser mwenje inodzoka inopinda zvakare mumusoro unobuda, uye kunyange chikamu chechiedza chinodzoka chinobatanidzwa mune simba-inotapurirana fiber, uye inofambiswa ichidzoka pamwe nefiber kusvika mukati. yelaser, ichiita kuti zvinhu zvakakosha mukati me laser zvirambe zviri pakupisa kwakanyanya.

Kana iyo reflectivity yakanyanya kukwira panguva yelaser welding, mhinduro dzinotevera dzinogona kutorwa:

3.1 Shandisa anti-reflection coating kana kubata pamusoro pechinhu: kupfekedza pamusoro peiyo welding zvinhu ne-anti-reflection coating inogona kunyatso kudzikisa kutaridzika kwelaser. Uku kupfekedza kunowanzo kuve kwakakosha optical material ine yakaderera reflectivity inotora laser simba panzvimbo yekuiratidza kumashure. Mune mamwe maitiro, akadai seazvino muunganidzi welding, yakapfava yekubatanidza, nezvimwe, iyo yepamusoro inogona zvakare kuisirwa.

3.2 Gadzirisa kona yewelding: Nekugadzirisa kona yewelding, iyo laser beam inogona kuitika pane welding zvinhu pane imwe kona yakakodzera uye kuderedza kuitika kwekuratidzwa. Kazhinji, kuva nelaser beam chiitiko perpendicularly kusvika pamusoro pechinhu chinosungirirwa inzira yakanaka yekudzikisa kuratidzwa.

3.3 Kuwedzera mubatsiri wemushonga: Munguva yekugadzira, imwe chiyero chekubatsira kunyura, sehupfu kana mvura, inowedzerwa kune weld. Aya maabsorber anotora laser simba uye anoderedza reflectivity. Iyo yakakodzera inopinza inoda kusarudzwa zvichibva pane chaiyo welding zvinhu uye mamiriro ekushandisa. Mune lithium bhatiri indasitiri, izvi hazvigoneke.

3.4 Shandisa optical fiber kuendesa laser: Kana zvichibvira, optical fiber inogona kushandiswa kuendesa laser kune welding chinzvimbo kuderedza reflectivity. Optical fibers inogona kutungamira laser danda kunzvimbo yewelding kudzivirira kuratidzwa kwakananga pamusoro peiyo welding zvinhu uye kuderedza kuitika kwekuratidzwa.

3.5 Kugadzirisa maparamendi e-laser: Nekugadzirisa maparamendi akadai sesimba relaser, kureba kwekutarisa, uye dhayamita yakatarisana, kugoverwa kwesimba relaser kunogona kudzorwa uye kuratidzwa kunogona kuderedzwa. Kune zvimwe zvinoratidzira zvinhu, kuderedza laser simba inogona kunge iri nzira inoshanda yekudzikisa kuratidzwa.

3.6 Shandisa danda rinopatsanura: danda rinopatsanura rinogona kutungamira chikamu cheiyo laser simba mumudziyo wekunyudza, nekudaro ichidzikisa kuitika kwekuratidzwa. Beam kupatsanura michina inowanzo sanganisira optical components uye absorbers, uye nekusarudza zvakakodzera zvikamu uye kugadzirisa marongerwo echishandiso, kuderera kwekuratidzira kunogona kuwanikwa.

4. Welding undercut

Mune iyo lithium bhatiri yekugadzira maitiro, ndeapi maitiro anonyanya kukonzera undercutting? Sei undercutting ichiitika? Ngatizviongorore.

Undercut, kazhinji machesero emagetsi haana kunyatsobatanidzwa pamwe chete, gaka rakakura zvakanyanya kana groove inooneka, kudzika uye hupamhi hwakakura kupfuura 0.5mm, hurefu hwacho hwakakura kupfuura 10% yehurefu hweweld, kana chikuru pane chigadzirwa process mwero urefu hwakumbirwa.

Mune iyo yese lithium bhatiri yekugadzira maitiro, undercutting inowanzoitika, uye inowanzo kugoverwa mukuisa chisimbiso pre-welding uye welding yecylindrical cover plate uye yekuisa chisimbiso pre-welding uye welding ye square aluminium shell cover plate. Chikonzero chikuru ndechekuti ndiro yekuvharisa yekuvharisa inoda kushandira pamwe negoko kune Welding, iyo nzira yekufananidza pakati pevhavha yekuvharira ndiro uye goko rinowanzo kune yakawandisa weld gaps, grooves, kudonha, nezvimwe, saka inonyanya kujaira kune undercuts. .

Saka chii chinokonzera undercutting?

Kana iyo welding yekumhanyisa ichimhanya zvakanyanya, iyo simbi yemvura kuseri kwegomba diki inonongedza pakati peiyo weld haizove nenguva yekugoverazve, zvichikonzera kusimba uye undercutting kumativi ese e weld. Tichifunga nezve mamiriro ari pamusoro, isu tinofanirwa kukwidziridza iwo welding paramita. Kuzvitaura zviri nyore, inodzokororwa kuyedza kuratidza akasiyana ma paramita, uye ramba uchiita DOE kusvika maparamita akakodzera awanikwa.

2. Kuwedzeredza weld gaps, grooves, kuputsika, nezvimwewo zve welding zvinhu zvinoderedza huwandu hwesimbi yakanyungudutswa ichizadza mapeji, zvichiita kuti undercuts iwedzere kuitika. Uyu mubvunzo wemidziyo uye zvigadzirwa. Ingave iyo welding mbishi zvinhu zvinosangana nezvinodiwa zvinouya zvemaitiro edu, kunyangwe iko iko kurongeka kwemidziyo kunoenderana nezvinodiwa, etc. Iyo yakajairika tsika ndeyekugara uchirwadzisa nekurova vatengesi uye vanhu vanotungamira michina.

3. Kana simba richidonha nekukurumidza pakupera kwelaser welding, gomba diki rinogona kudonha, zvichikonzera kuderedzwa kwenzvimbo. Iko kuenzanirana kwesimba uye kumhanya kunogona kudzivirira zvinobudirira kuumbwa kwe undercuts. Sezvo chirevo chekare chichienda, dzokorora zviedzo, simbisa ma paramita akasiyana, uye enderera mberi neDOE kusvika wawana ma paramita akakodzera.

5. Weld centre kuparara

Kana iyo welding inokurumidza kunonoka, dziva rakanyungudutswa richava rakakura uye rakakura, richiwedzera huwandu hwesimbi yakanyungudutswa. Izvi zvinogona kuita kuti kuchengetedza kwepamusoro kuve kwakaoma. Kana simbi yakanyungudutswa ikanyanya kurema, pakati peiyo weld inogona kunyura uye kuita dips nemakomba. Muchiitiko ichi, simba remagetsi rinoda kuderedzwa zvakakodzera kudzivirira kunyunguduka kwedziva.

Mune imwe mamiriro ezvinhu, gaka rekushongedza rinongogadzira kudonha pasina kukonzera kupera. Iri pasina mubvunzo idambudziko remichina press fit.

Kunzwisisa kwakaringana kwehurema hunogona kuitika panguva yelaser welding uye zvikonzero zvekukanganisa kwakasiyana kunobvumira nzira yakanangwa yekugadzirisa chero matambudziko asina kujairika welding.

6. Weld mitswe

Mitswe inooneka panguva inoenderera mberi nelaser welding inonyanya kupisa kupisa, senge crystal cracks uye liquefaction cracks. Chikonzero chikuru chekutsemuka uku ndiko kuderera kukuru kwemasimba anogadzirwa ne weld isati yanyatsosimba.

Kune zvakare zvikonzero zvinotevera zvekutsemuka mune laser welding:

1. Kusanzwisisika weld dhizaini: Zvisizvo dhizaini yejometri uye saizi yeweld inogona kukonzera welding kusagadzikana kushushikana, nekudaro zvichikonzera kuputika. Mhinduro ndeyekukwenenzvera weld dhizaini kudzivirira welding kusagadzikana kushushikana. Iwe unogona kushandisa akakodzera offset welds, shandura iyo weld chimiro, nezvimwe.

2. Mismatch yemaparamendi ewelding: Kusarudzika kwakashata kwezviyereso zvewelding, senge kukurumidza kukurumidza welding, yakanyanya simba, zvichingodaro, zvinogona kutungamirira kune kusaenzana kwekushisa kushanduka munzvimbo yewelding, zvichikonzera kushushikana kukuru uye kutsemuka. Mhinduro ndeyekugadzirisa iyo welding parameters kuti ienderane neiyo chaiyo zvinhu uye welding mamiriro.

3. Kusagadzikana kwekugadzirisa kwepamusoro-soro: Kusakwanisa kuchenesa uye kusati kwatanga kuchenesa nzvimbo yemoto isati yanyungudutswa, zvakadai sokubvisa okisidhi, girisi, nezvimwewo, zvichakanganisa kunaka uye simba re weld uye nyore nyore kutungamirira kune kuputika. Mushonga wacho ndewekuchenesa zvakakwana uye kusati kwatanga kurapa kwechimbichimbi kuti uone kuti kusvibiswa uye kusvibiswa munzvimbo yewelding zvinogadziriswa.

4. Kudzora kusina kunaka kwekupisa kwekupisa kwekupisa: Kutadza kutonga kwekupisa kwekupisa panguva yekuputika, zvakadai sekupisa kwakanyanya panguva yekuputika, kutonhora kusina kunaka kwechigadziko chewelding, zvichingodaro, zvinotungamirira kuchinja kwechimiro chenzvimbo yewelding, zvichiita kuti pave nekuputika. . Mhinduro ndeyekudzora tembiricha uye kutonhora mwero panguva yewelding kudzivirira kupisa uye nekukurumidza kutonhora.

5. Kusakwana kwekunetseka kwekunetseka: Kusakwana kwekugadzirisa kushungurudza kurapwa mushure mekuputika kuchaita kuti kusakwana kwekunetseka kwekunetseka munzvimbo yakasungirirwa, iyo ichaita nyore nyore kuputika. Mhinduro ndeyekuita kwakakodzera kunyaradza kushushikana kurapwa mushure mekudzikisira, senge kupisa kupisa kana vibration kurapwa (chikonzero chikuru).

Kana iri yekugadzira mabhatiri e-lithium, ndeapi maitiro anonyanya kukonzera kutsemuka?

Kazhinji, kutsemuka kunowanzoitika panguva yekuisa chisimbiso, sekuisa chisimbiso che cylindrical simbi shells kana aluminium shells, kuisa chisimbiso chesquare aluminium shells, nezvimwewo. Pamusoro pezvo, panguva yekuisa chisimbiso chemodule, kusungirirwa kwemuunganidzi wemazuva ano kunowanzoitikawo. kutsemuka.

Ehe, isu tinogona zvakare kushandisa filler waya, preheating kana dzimwe nzira kuderedza kana kubvisa makatsemuka aya.

Nguva yekutumira: Sep-01-2023