Saizi yeiyo laser core dhayamita ichakanganisa kutapurirana kurasikirwa uye simba density kugovera kwechiedza. Kusarudzwa kunonzwisisika kwepakati dhayamita kwakakosha zvikuru. Yakawandisa musimboti dhayamita inotungamira kumodhi kukanganiswa uye kupararira mukufambiswa kwelaser, zvichikanganisa kunaka kwedanda uye kutarisisa kurongeka. Yakanyanya kudiki dhayamita yepakati inokonzeresa Iyo symmetry ye optical simba density ye single-mode fiber inova yakaipisisa, iyo isingakodzeri kutapuriranahigh-simba laser.

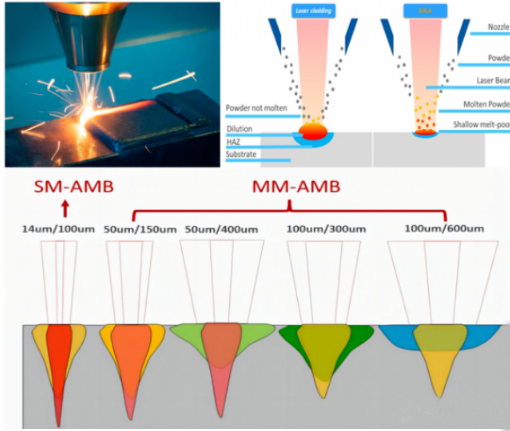

1. Zvakanakira uye mashandisirwo ediki core dhayamita lasers (<100um)

Zvinhu zvinoratidzira zvakanyanya: aluminium, mhangura, simbi isina tsvina, nickel, molybdenum, nezvimwewo;

(1)Zvinhu zvinoratidzira zvakanyanya zvinoda kusarudza diki diki dhayamita laser. Iyo yakakwira simba density laser beam inoshandiswa kukurumidza kupisa zvinhu kune liquefied kana vaporized state, iyo inovandudza iyo laser yekunyudza chiyero chechinhu uye inobudirira uye nekukurumidza kugadzirisa. Kusarudza laser ine hombe yepakati dhayamita inogona kutungamira kune yakakwira kufungisisa. , inotungamira kune virtual welding uye kunyange kupisa kwelaser;

Crack-sensitive zvinhu: nickel, nickel-plated mhangura, aruminiyamu, Stainless simbi, titanium alloy, nezvimwe.

Ichi chinyorwa chinowanzoda kudzora kwakasimba kwenzvimbo yakakanganiswa nekupisa uye dziva diki rekunyungudika, saka zvakanyanya kufanira kusarudza diki dhayamita yepakati laser;

(3)Yakadzika yekupinda welding inoda yakakwira-kumhanya laser processing, uye zvinodikanwa kusarudza laser ine yakakwira simba density kuti ive nechokwadi chekuti mutsara simba rinokwana kunyungudutsa zvinhu nekumhanya kwakanyanya, kunyanya pamakumbo welding, penetration welding, nezvimwewo, zvinoda kudzika kwepamusoro kwekupinda. Zviri nani kusarudza diki yepakati dhayamita laser yakakodzera.

2. Zvakanakira uye mashandisirwo emahombe epakati dhayamita lasers (> 100um)

Yakakura yepakati dhayamita uye nzvimbo hombe, hombe yekuvhara nzvimbo yekudziya, yakafara nzvimbo yekuita, uye chete micro-kunyunguduka kwechinhu chepamusoro kunowanikwa, iyo yakakodzera kwazvo kunyorera mu laser cladding, laser remelting, laser annealing, laser kuomesa, nezvimwe. minda iyi, hombe chiedza chivara zvinoreva yakakwirira kugadzirwa kunyatsoshanda uye yakaderera kuremara (thermal conductive welding ine anenge asina kuremara).

Pane zvewelding, nzvimbo huru inonyanya kushandiswacomposite welding, iyo inoshandiswa kusanganisa nediki diki dhayamita laser: iyo nzvimbo hombe inoita kuti pamusoro pechinhu chinyunguduke zvishoma, kushandura kubva pakasimba kuenda kumvura, iyo inovandudza zvakanyanya kunyudzwa kwechinhu kune laser, uyezve inoshandisa diki core In. maitiro aya, nekuda kwekupisa kwenzvimbo hombe, post-processing, uye hombe tembiricha gradient yakapihwa dziva rakanyungudutswa, zvinhu zvacho hazvitani kutsemuka hurema hunokonzerwa nekukurumidza kupisa uye nekukurumidza kutonhora. Inogona kuita kuti kutaridzika kweiyo weld kupfave uye kuwana yakaderera spatter pane imwechete laser mhinduro.

Nguva yekutumira: Sep-04-2023