Muna Ndira 2023, makambani mazhinji eChinese akazivisa hurongwa hwekuwedzera simba uye simba rekuchengetera mabhatiri, nemari yekudyara inosvika zana remabhiriyoni eyuan uye yakasanganiswa yekugadzira ye269 GWh, inodarika iyo yakasanganiswa kugadzirwa muhafu yekutanga yegore rapfuura (206.4 GWh. ) uye inenge ichivhara gore rapfuura yakaiswa simba remba bhatiri kudiwa (294.6 GWh)

| Enterprise | Mari yekudyara (bhiriyoni) | Kukwanisa kugadzira (GWh) |

| BYD | 10 (Inofungidzirwa) | 35 |

| EVE BATTERY | 20.8 | 80 |

| Ganfeng Lithium | 15 | 34 |

| BAK BATTERY | 13 | 30 |

| Farasis Energy | 10 | 30 |

| Shenghong Group | 30.6 | 60 |

| Total | 99.4 | 269 |

Data source: China Automotive Nhau, network yeruzhinji data

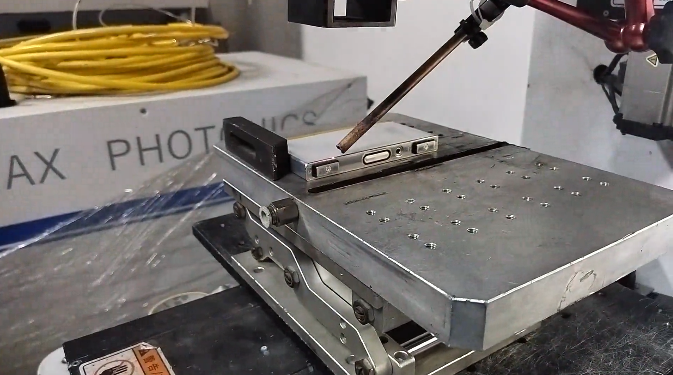

Munguva yekugadzirwa kwemabhatiri emagetsi, kugadzikana kwemhando yebhatiri shell welding kuchakanganisa kuenderana uye kuchengetedzeka kwebhatiri musangano system. Iyo yemukati yesimba bhatiri goko rinonyanya kuve ne organic electrolyte, yakakosha diaphragm, uye chivharo chinonyanya kuve nekuputika-proof valve, pole post, kuchengetedza kavha, liquid jekiseni gomba, nezvimwe. uye kunaka kwayo kunobata zvakananga dhigirii yekuisa chisimbiso yebhatiri, uye kushata kwakashata kunotungamira mukudonha kwebhatiri, lithium precipitation, uye kutaridzika kwebhatiri hakusi kusvika pachiyero.

▲Hard-shell square lithium bhatiri solder

01 Zvakajairwa welding seam matambudziko

1- Chitarisiko chakashata: welding bias, maziso ejecha, sample tilt

2- Simba risina kukwana uye chisimbiso: kusakwana kudzika kwekusanganiswa, kutsemuka, makomba makuru emhepo anokonzera kubuda kwebhatiri.

02 Kuongororwa kwemaitiro ekugadzirisa matambudziko seam

Zvinoenderana neiyo FTA yekukanganisa ongororo, iyo welding yekutadza dambudziko rinonyanya kupfupikiswa seyakaipa chitarisiko uye welding simba matambudziko. Zvakaipa chitarisiko zvinhu: welding midziyo yeCCD yekutarisisa kufambira mberi, yekudzivirira gasi rudzi uye kuyerera mwero, welding sampuli kuchena, sampuli mechanicha yakakodzera uye nzira. Welding simba uye yekuisa chisimbiso zvinhu: mbishi zvinhu zvine chaiyo, aluminium kuumbwa, kukanganisa kwemaitiro paramita.

| Classification | Mibvunzo | Maitiro Anokonzera Categorization | Zvikonzero zvakananga |

|

Chitarisiko | Partial welding | Welding nzira Kuzivikanwa uye kuiswa | Iyo CCD yekuona yekumisikidza maitiro haigone kunyatso ratidza sampuli maficha, zvichikonzera kutsauswa welding trajectories, kusakwana kuratidzwa kweanobatsira mwenje sosi kumuenzaniso, uye kuwedzera kuoma mukumisikidza mafoto. |

| Trachoma air gole | The zvinhu pachayo uye welding nharaunda | Aluminium shell material kuumbwa, kugadzika kusina kunaka kwemhando yekudzivirira gasi uye chiyero chekuyerera, kuenzanisa kusina kukodzera kwepamusoro welding nzira uye weld gap yevhavha uye shell, kusakwana kwehutsanana hweparutivi welding kana welding welding nzvimbo. | |

| Muenzaniso kusaenzana | Sample musangano kururama | Kavha uye goko repamusoro welding nzira weld gap inokodzera zvisizvo, welding process stress kuunganidza. | |

| Welding simba | Battery leakage | Sample saizi kukanganisa uye pesvedzero yewelding paramita | Iyo chivharo uye goko rakakodzera saizi haina kugadzikana, uye maitiro paramita haana kuisirwa nemazvo. |

03 Basa rekudzivirira gasi

Dziviriro gasi mune laser welding process inogona kudzivirira oxidation yesimbi pamusoro, kudzivirira lens, kuvhuvhuta plasma, inoda kudzora mafambiro emhepo, kudzvanywa, kuyerera. Iyo inodzivirira gasi inoumba mhirizhonga, iyo weld ichave ine porosity, isina kuenzana weld seam uye mamwe matambudziko.

04 Yakasiyana gasi maitiro

Mhando dzemagasi ekudzivirira ekuisa laser welding anosanganisira helium, argon uye nitrogen

Helium: Yakakwira dhigirii yeionization, iyo laser inogona kupfuura, iyo yese danda simba rinosvika pamusoro peiyo workpiece, kwete nyore kugadzira porosity, asi inodhura.

Argon: mutengo wakaderera pane helium, asi inotapukira kune yakanyanya tembiricha yeplasma ionization, kunyangwe iyo yekudzivirira iri nani, asi inodzivirira chikamu cheiyo laser simba rekugadzirisa, kuderedza simba relaser, kushandiswa kwehelium welding surface kutaridzika zvakanaka.

Nitrogen: mutengo wakaderera, ionization diki, welding kuzvimba kunopindirana nezvimwe zvinhu zvealuminium alloy kugadzira makomisheni asina kugadzikana, anokanganisa simba rewelding.

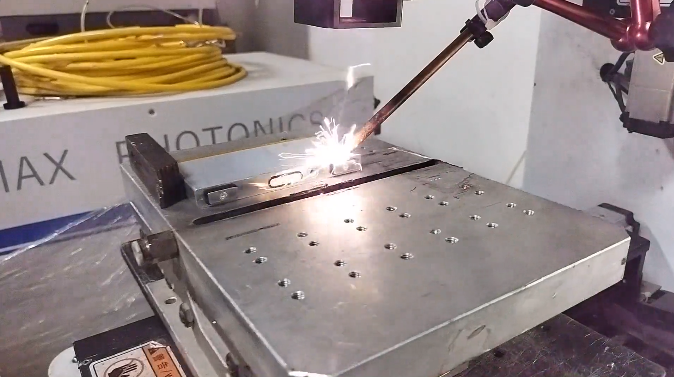

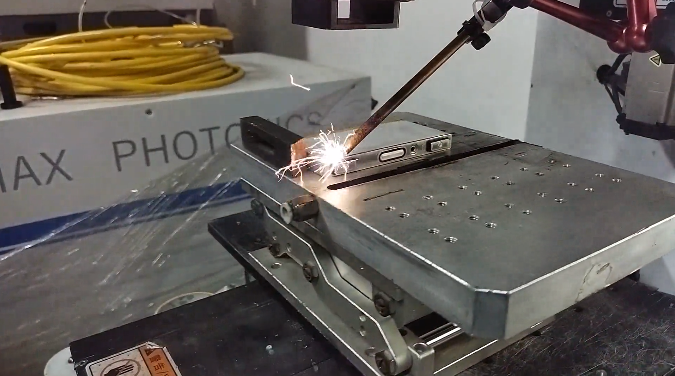

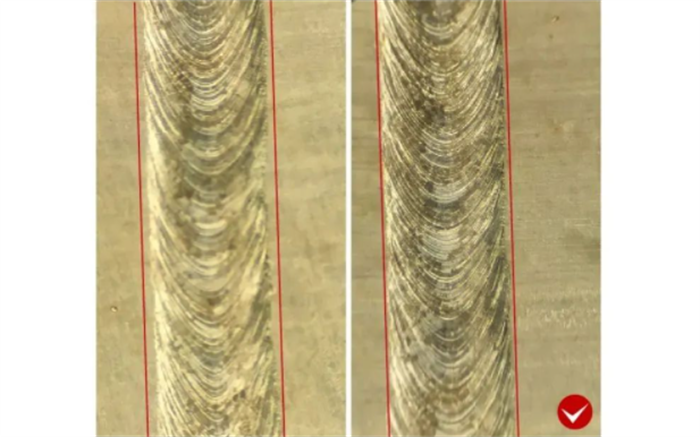

05 Ongororo yemhedzisiro yeakasiyana welding mamiriro

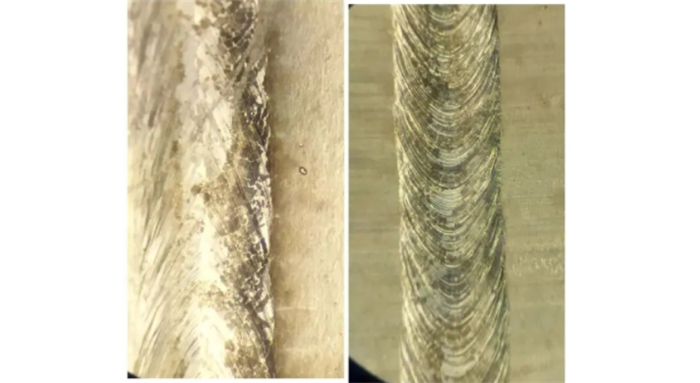

Welding ne nitrogen uye argon segasi rinodzivirira, kana uchishandisa nitrogen seyekudzivirira gasi, weld upamhi hunoenderana husina kunaka, uchishandisa argon sekudzivirira gasi, kuvhura weld kunotsvedzerera, chiyero chehove chakagadziridzwa zvakaenzana, uye kutaridzika kuri nani pane kushandisa. nitrogen welding zvigadzirwa. (Sezvinoratidzwa mumufananidzo uri pasi apa)

▲ Different shielding gas welding effect (yakasiyana musono upamhi kuenderana)

Laser simba pamusoro pezvinoita welding, uchishandisa zvakafanana welding kumhanya uye kudzivirira gasi, iyo yakakwirira chaiyo simba goho, kukurumidza iyo weld zvinhu zvinogona kunyungudutswa uye vaporized, iyo inonyunguduka dziva fluidity inowedzera, iyo hove chikero patani pechiso chakanyanya yunifomu, musono we weld wakanyanya flat. (Sezvinoratidzwa mumufananidzo uri pasi apa)

▲ Simba rakasiyana-siyana welding effect (yakasiyana pamusoro pekufanana)

Summary

1. kune terminal saiti laser sealing equipment, CCD scanning positioning uye welding parameters ine chekuita pakuonekwa kwezvakaipa mudambudziko re partial welding.

2. Kudzivirirwa gasi rudzi uye parameter zvigadziriso zvinogona kuvandudza yunifomu kuwirirana kwe weld, kuve nechokwadi chekuchena kwenzvimbo yewelding, kuderedza kuiswa kwekusvibiswa kune dzimwe nyika, kunogona kuderedza welding slag inogadzirwa ne trachoma porosity.

3. Mechanical kufanira pamusoro pakakoromoka kufanira zviri nani pane kupindira kwakakodzera, munda welding muitiro kutanga gwapa welding uye ipapo kuramba nomoto nzira, anogona zvikuru kugadzirisa gaka kufanira apo nomoto kugadzikana matambudziko.

Maven Laser ikambani yelaser indasitiri yakatarisana, yakavambwa muna 2008, ikozvino ine makore mashanu ehunyanzvi hweindasitiri mumunda welaser welding, inyanzvi pakusarudza akanyanya kukodzera laser welding mhinduro uye yekufananidza laser welding michina yako. Muna Ndira, takatangisa yedu yazvino laser air-yakatonhorera handheld welding muchina, uyo wave munguva yakakosha yekusimudzira, tenga mashanu mayunitsi, mutengo wechikamu chimwe wakaderera semadhora mazana mana nemakumi mashanu, tenga gumi, mutengo wechikamu chimwe chete. yakaderera kusvika ku4200 $. Mhepo-yakatonhodzwa handheld welding idiki, yakanakira welding yekunze, uye Maven's air-yakatonhorera handheld laser welding muchina inogadzirisa iripo muchina kupisa dissipation dambudziko uye inogona kushanda kwenguva yakareba pasina kukanganisa. Kugamuchirwa kubvunza kwako! Isu tiri Maven Laser, wako nyanzvi laser shamwari.

Nguva yekutumira: Mar-03-2023