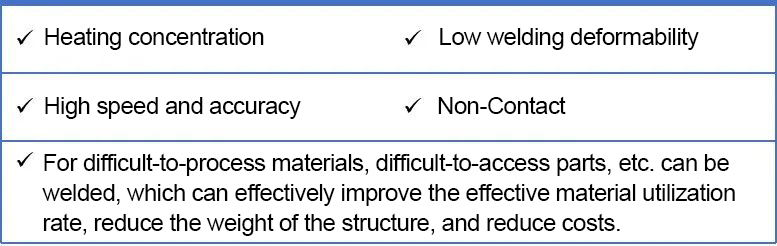

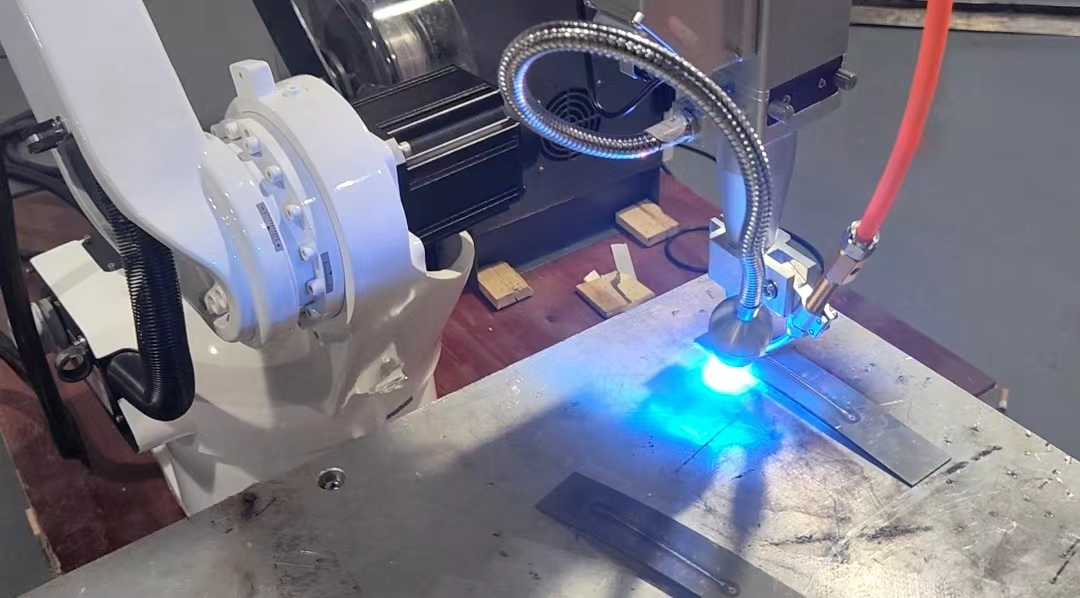

Laser kujoinha tekinoroji, kana laser welding tekinoroji, inoshandisa yakakwira simba laser danda kutarisisa uye kudzora kuvhenekesa kwechinhu chepamusoro, uye nzvimbo yepasi inotora simba relaser uye inoshandura kuita simba rekupisa, zvichiita kuti zvinhu zvipise uye zvinyunguduke. , inoteverwa nekutonhodza uye kusimba kuti uwane kujoinwa kwehomogeneous kana dissimilar zvinhu. Iyo laser welding process inoda laser simba density yegumi4ku108W/cm2. Kuenzaniswa nemaitiro echinyakare welding, laser welding ine zvinotevera zvakanakira.

Laser kujoinha tekinoroji, kana laser welding tekinoroji, inoshandisa yakakwira simba laser danda kutarisisa uye kudzora kuvhenekesa kwechinhu chepamusoro, uye nzvimbo yepasi inotora simba relaser uye inoshandura kuita simba rekupisa, zvichiita kuti zvinhu zvipise uye zvinyunguduke. , inoteverwa nekutonhodza uye kusimba kuti uwane kujoinwa kwehomogeneous kana dissimilar zvinhu. Iyo laser welding process inoda laser simba density yegumi4ku108W/cm2. Kuenzaniswa nemaitiro echinyakare welding, laser welding ine zvinotevera zvakanakira.

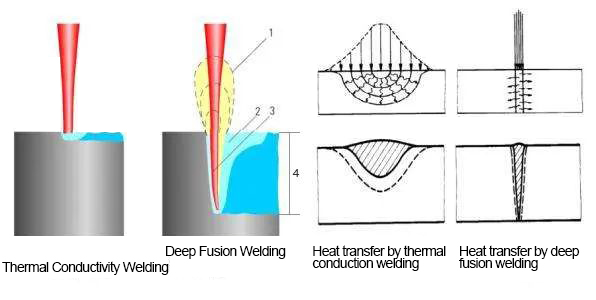

1-plasma gore, 2-inonyunguduka zvinhu, 3-kiyi hole, 4-yakadzika yefusion

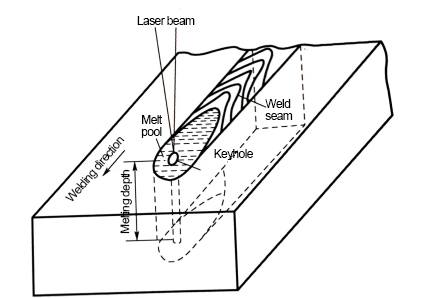

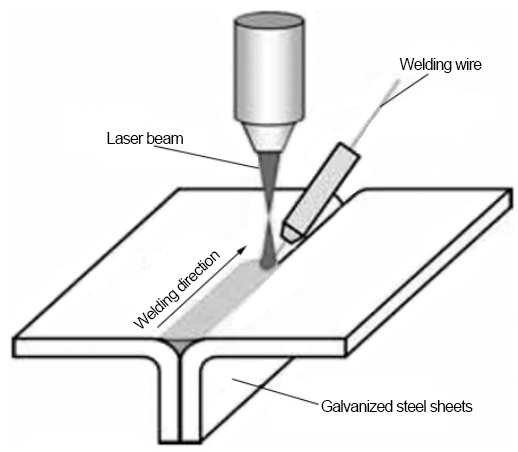

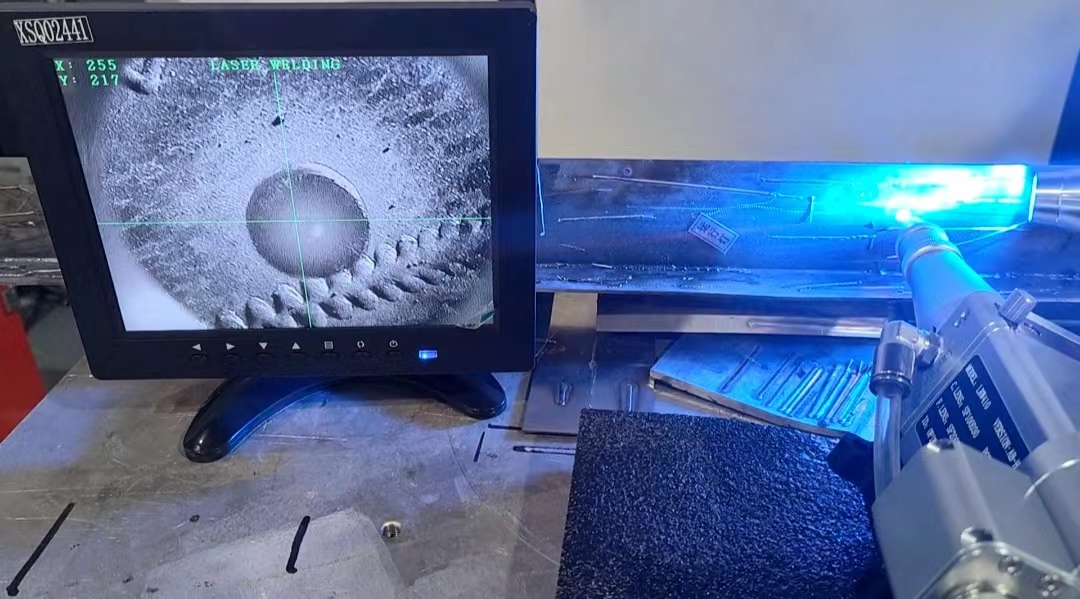

Nekuda kwekuvapo kwegomba rekiyi, iro laser beam, mushure mekuvhenekesa mukati megomba rekiyi, rinowedzera kutorwa kwelaser nechinhu uye kusimudzira kuumbwa kwedziva rakanyungudutswa mushure mekupararira uye zvimwe zvinokonzeresa, nzira mbiri dzekushongedza dzinofananidzwa. sezvinotevera.

Nhamba iri pamusoro apa inopa laser welding process yechinhu chimwe chete nemwenje sosi, simba rekushandura simba rinoitwa chete kuburikidza nekiyi hole, kiyi hole uye simbi yakanyungudutswa padyo nemadziro egomba inofamba nekumberi kwelaser beam, simbi yakanyungudutswa inobvisa buri rekiyi kubva kumhepo yakasara kumashure kuti izadze uye mushure mekugwinya, ichiita musono we weld.

Kana iyo inoiswa welded iine simbi yakasiyana, kuvepo kwekusiyana kwezvinhu zvinopisa kuchava nekukanganisa kukuru pakuita kwechikafu, sekusiyana kwenzvimbo dzekunyungudika, kupisa kwekushisa, huwandu hwekupisa, uye kuwedzera coefficients yezvinhu zvakasiyana, zvichikonzera. mune welding kushushikana, welding deformation, uye shanduko mumamiriro ekristalllization eiyo welded joint metal, zvichikonzera kuderera kwema mechanical properties ye weld.

Naizvozvo, zvinoenderana neakasiyana hunhu hwenzvimbo yewelding, iyo welding process yakagadzira laser filler welding, laser brazing, dual-beam laser welding, laser composite welding, nezvimwe.

Laser Wire Kuzadza Welding

Mune laser welding process yealuminium, titanium nemhangura alloys, nekuda kwekudzika kwakadzika kwelaser light (<10%) mune izvi zvinhu, iyo foto inogadzirwa plasma ine kumwe kudzivirirwa kwelaser light, saka zviri nyore kuumba spatter uye. kutungamirira kuchizvarwa chezvirema zvakadai seporosity uye kuputika. Uye zvakare, iyo welding mhando inokanganiswa zvakare kana mukaha uri pakati pezvishandiso wakakura pane iyo dhayamita yenzvimbo panguva yakatetepa ndiro yekupuruzira.

Mukugadzirisa matambudziko ari pamusoro apa, zviri nani welding mhedzisiro inogona kuwanikwa nekushandisa nzira yekuzadza zvinhu. Iyo yekuzadza inogona kuve waya kana hupfu, kana pre-set yekuzadza nzira inogona kushandiswa. Nekuda kwenzvimbo diki yakatariswa, weld inova diki uye ine zvishoma convex chimiro pamusoro pepamusoro mushure mekuisa zvinhu zvekuzadza.

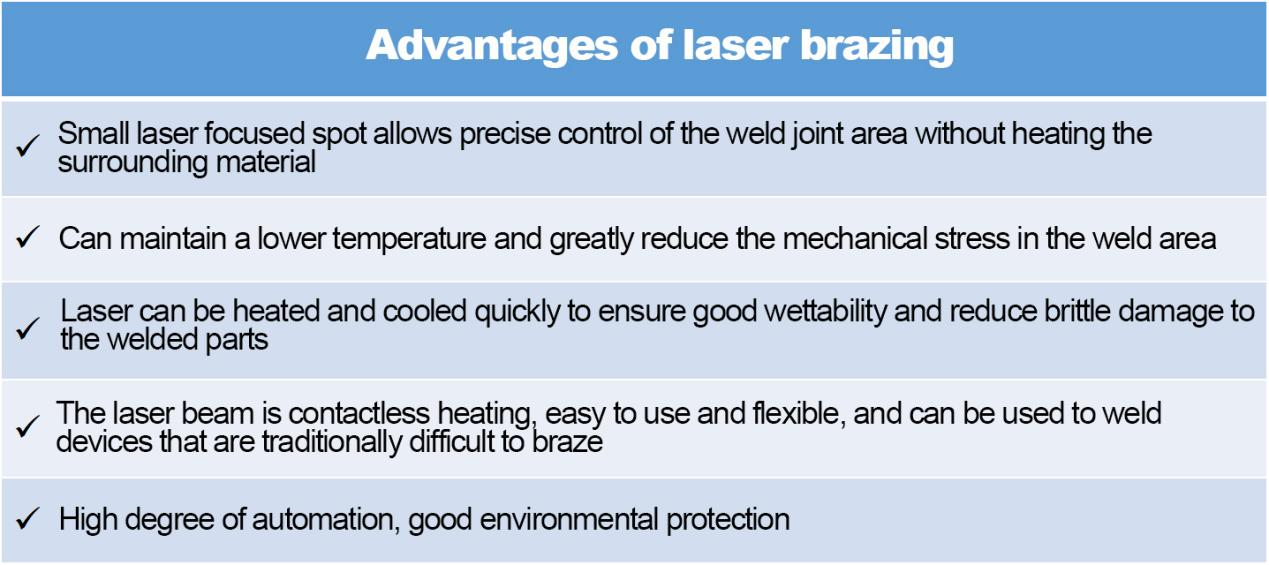

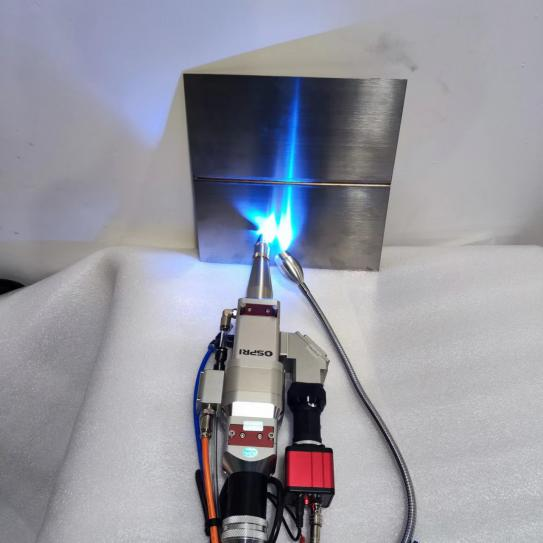

Laser Brazing

Kusiyana nefusion welding, iyo inonyungudutsa zvikamu zviviri zvakakanyiwa panguva imwe chete, brazing inowedzera yekuzadza zvinhu ine yakaderera kunyungudika pane iyo base zvinhu kune weld pamusoro, inonyungudutsa iyo yekuzadza zvinhu kuzadza gap patembiricha yakaderera kupfuura kunyungudika kwezvinhu. poindi uye yakakwira kupfuura panonyungudika chinhu chekuzadza, uye yobva yaita kuti iite yakasimba weld.

Brazing inokodzera kupisa-sensitive microelectronic madivayiri, mahwendefa matete, uye simbi inoputika.

Kupfuurirazve, inogona kuverengerwa zvakare seyakapfava brazing (<450 ° C) uye yakaoma brazing (> 450 ° C) zvichienderana nekupisa uko kunopisa zvinhu.

Dual Beam Laser Welding

Dual-beam welding inobvumira kuchinjika uye nyore kudzora kwelaser irradiation nguva uye chinzvimbo, nekudaro kugadzirisa kugovera kwesimba.

Inonyanya kushandiswa laser welding yealuminium uye magnesium alloys, splice uye lap plate welding yemotokari, laser brazing uye yakadzika fusion welding.

Iyo kaviri danda inogona kuwanikwa neaviri akazvimirira lasers kana nekutsemura danda nedanda rakapatsanura.

Iyo matanda maviri anogona kunge ari musanganiswa we lasers ane akasiyana nguva domain maitiro (pulsed vs. inoenderera), akasiyana wavelengths (pakati-infrared vs. inooneka wavelengths) uye masimba akasiyana, ayo anogona kusarudzwa maererano nechaiyo yakagadziriswa zvinhu.

4.Laser Composite Welding

Nekuda kwekushandiswa kwelaser beam seyo chete kupisa sosi, single heat source laser welding ine yakaderera simba rekushandura chiyero uye chiyero chekushandisa, iyo weld base material port interface iri nyore kugadzira misalignment, nyore kugadzira pores uye makatsemuka uye kumwe kukanganisa, kuti ugadzirise dambudziko iri, unogona kushandisa maitiro ekudziya emamwe masosi ekupisa kuti uvandudze kupisa kwelaser pane workpiece, inowanzonzi laser composite welding.

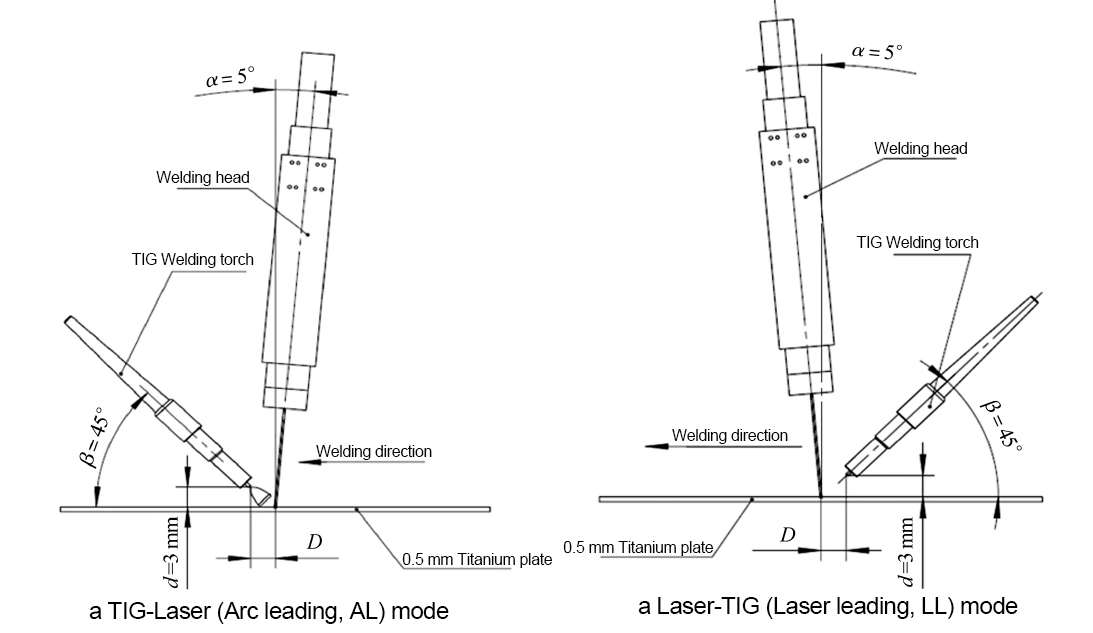

Iyo huru fomu yelaser composite welding ndeye composite welding yelaser uye yemagetsi arc, 1 + 1> 2 maitiro ndeaya anotevera.

mushure me laser beam padhuze neyakaiswa arc,iyo electron density yakanyanya kuderedzwa, gore replasma rinogadzirwa nelaser welding rinoderedzwa, iroinogona kuita kuti laser absorption rate ivandudzwe zvakanyanya, nepo arc pane base zvinhu preheating ichawedzera kuwedzera kunyudzwa kweiyo laser.

2. kushandiswa kwesimba kwepamusoro kwearc uye yakazarakushandiswa kwesimba kuchawedzerwa.

3, iyo laser welding nzvimbo yechiito idiki, iri nyore kukonzera misalignment yewelding port, nepo thermal action yearc yakakura, inogonakuderedza kusarongeka kweiyo welding port. Panguva imwecheteyo, thewelding quality uye kushanda zvakanaka kwearc kunovandudzwanekuda kwekutarisa uye kutungamira mhedzisiro yelaser beam pane arc.

4, laser welding ine yakakwirira peak tembiricha, hombe-yakakanganiswa nzvimbo, kutonhora nekukurumidza uye kusimba kwekusimbisa, nyore kugadzira makatsemuka uye pores; nepo arc's inopisa-yakakanganiswa nzvimbo idiki, inogona kuderedza tembiricha gradient, kutonhora, kusimba kumhanya,inogona kuderedza uye kubvisa chizvarwa chepores uye kuputika.

Pane nzira mbiri dzakajairika dzelaser-arc composite welding: laser-TIG composite welding (sezvinoratidzwa pazasi) uye laser-MIG composite welding.

Kune zvakare mamwe mafomu ewelding akadai selaser uye plasma arc, laser uye inductive heat source compound welding.

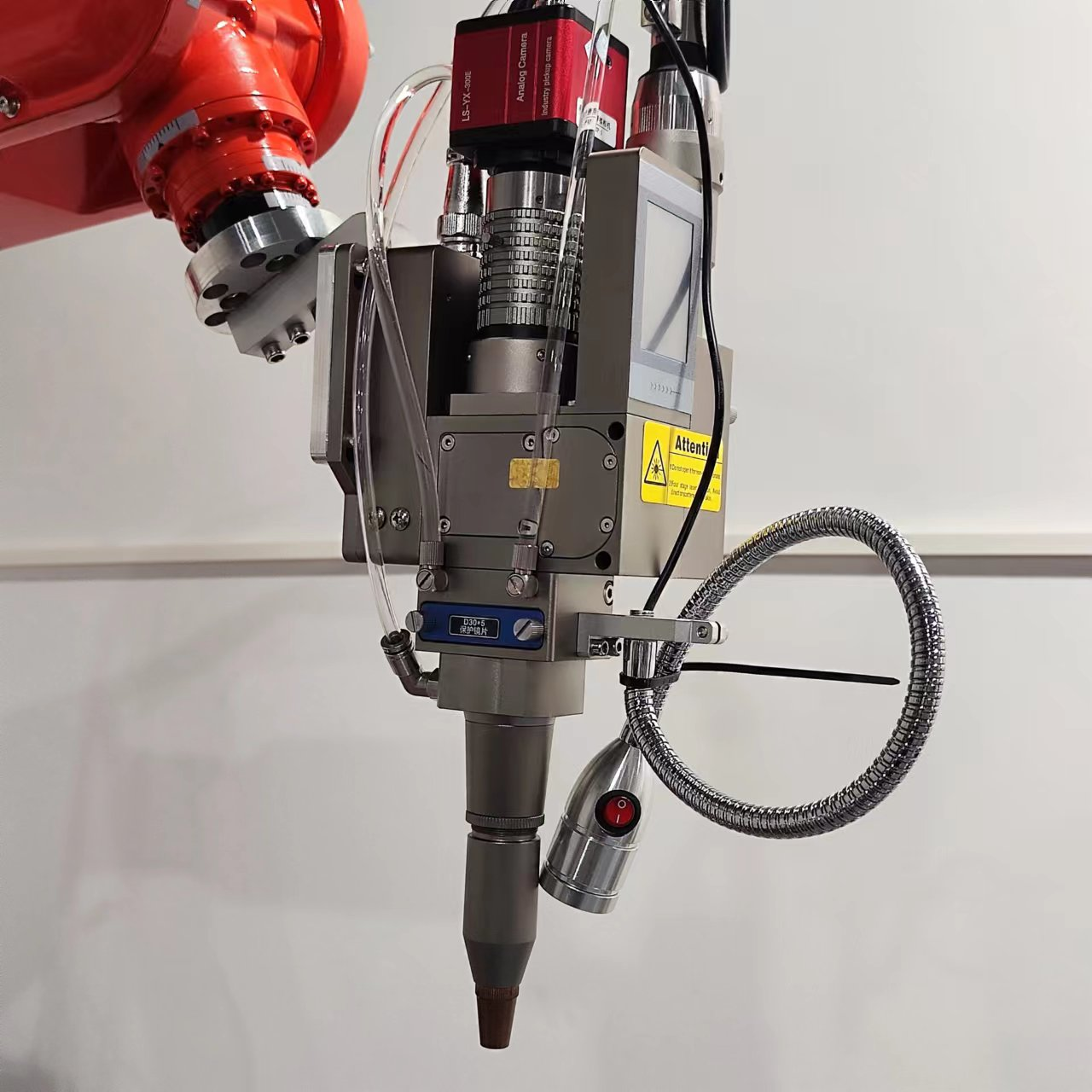

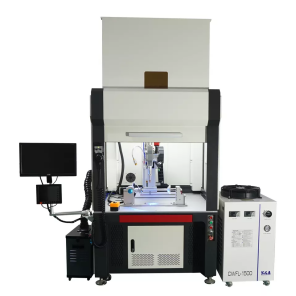

About MavenLaser

Maven Laser ndiye mutungamiri welaser industrialization application muChina uye ane mvumo mupi wepasi rose laser kugadzirisa mhinduro. Isu tinobatisisa maitiro ekusimudzira indasitiri yekugadzira, tinogara tichipfumisa zvigadzirwa zvedu nemhinduro, tichiomerera pakuongorora kubatanidzwa kweautomation, informationization uye hungwaru neindasitiri yekugadzira, kupa laser welding michina, laser yekumaka michina, laser yekuchenesa michina uye laser goridhe uye sirivheri zvishongo. kucheka michina yemaindasitiri akasiyana siyana anosanganisira akazara emagetsi akateedzana, uye nekuramba tichiwedzera pesvedzero yedu mumunda wemidziyo yelaser.

Nguva yekutumira: Jan-13-2023