Laser kuchenesa inzira inoshanda yekubvisa iyo yakasimba pamusoro pezvinhu zvakasiyana uye saizi yetsvina particles uye firimu layer. Kuburikidza nekupenya kwepamusoro uye yakanaka inoenderera mberi kana pulsed laser, kuburikidza nekutarisa kwemaziso uye kuumbwa kwemavara kuti iite yakasarudzika nzvimbo uye kugovera simba kwelaser beam, yakavhenekerwa pamusoro pechinhu chakasvibiswa kuti chicheneswe, izvo zvakasungirirwa zvinosvibisa zvinotora laser. simba, richagadzira nhevedzano yeakaomesesa emuviri uye kemikari maitiro senge vibration, kunyunguduka, kupisa, uye kunyange gasification, uye pakupedzisira kugadzira iyo inosvibisa kubva pamusoro pechinhu Kunyange kana laser chiitiko pane yakacheneswa nzvimbo, iyo yakawanda inoratidzwa. kure, iyo substrate haizokonzerese kukanganisa, kuitira kuti uwane iyo yekuchenesa maitiro.Mufananidzo unotevera: shinda pamusoro pekubvisa ngura uye kuchenesa.

Laser yekuchenesa inogona kuverengerwa zvinoenderana neakasiyana emhando zviyero. Zvakadai sekuenderana nelaser yekuchenesa maitiro pane substrate pamusoro yakafukidzwa neyemvura firimu yakakamurwa kuita yakaoma laser kuchenesa uye wet laser kuchenesa. Iyo yekutanga ndiyo yakananga irradiation yelaser inosvibisa nzvimbo, iyo yekupedzisira inoda kuiswa kune iyo laser yekuchenesa pamusoro pemvura kana firimu remvura. Kunyorova laser kucheneswa kwekushanda kwepamusoro, asi iyo laser wet yekuchenesa inoda manyore yekuputira yemvura firimu, iyo inoda iyo yemvura firimu kuumbwa haigone kushandura chimiro cheiyo substrate zvinhu pachazvo inochinja. Naizvozvo, zvine hukama neyakaoma laser yekuchenesa tekinoroji, yakanyorova laser kuchenesa kune zvimwe zvinogumira pachiyero chekushandisa. Dry laser kuchenesa parizvino ndiyo inonyanya kushandiswa laser yekuchenesa nzira, iyo inoshandisa laser danda kuvhenekesa pamusoro peiyo workpiece zvakananga kubvisa zvimedu uye matete mafirimu.

LaserDry Cleaning

Nheyo yekutanga yelaser yakaoma yekuchenesa ndiyo chidimbu uye iyo substrate yemidziyo nelaser irradiation, iko kutendeuka kwekukurumidza kwesimba rechiedza rakanyura mukupisa, zvichikonzera chidimbu kana substrate kana zvese zviri zviviri kuwedzera kwekupisa kwemafuta, pakati pechikamu uye substrate ipapo yakagadzira kukurumidza, simba rinogadzirwa nekukasira kukunda adsorption pakati pechikamu uye substrate, kuitira kuti chidimbu chinobva kune substrate pamusoro.

Zvinoenderana neyakasiyana nzira dzekunyudza dzelaser yakaoma yekuchenesa, laser yakaoma yekuchenesa inogona kukamurwa kuita maviri anotevera mafomu makuru:

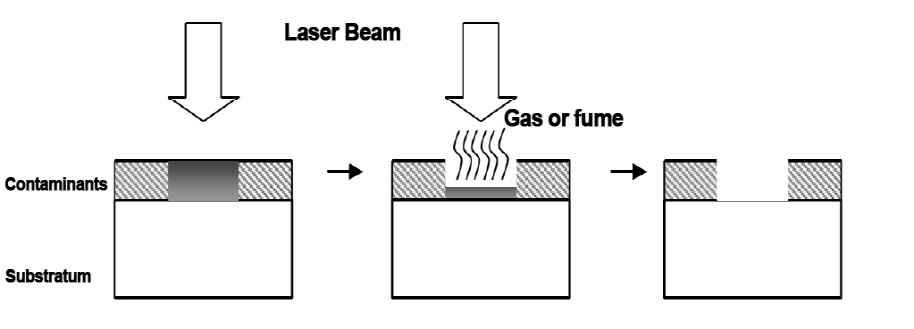

1.Fkana nzvimbo yakanyunguduka yakakura kupfuura iyo yevabereki zvinhu (kana laser absorption rate misiyano) yeguruva zvidimbu: zvimedu zvinotora laser irradiation yakasimba kudarika kunyudzwa kweiyo substrate (a) kana zvinopesana (b), ipapo zvimedu zvinotora laser mwenje. simba rinoshandurwa kuita simba rinopisa, richikonzera kuwedzera kwemafuta ezvimedu, kunyange zvazvo huwandu hwekuwedzera kwekupisa huri hudiki, asi kuwedzera kwekupisa kuri munguva shoma shoma, saka pachava nekukasira kukuru kwekukurumidza pane substrate, nepo substrate counter-action pane zvimedu, simba rekukunda iyo mutual adsorption simba, kuitira kuti zvimedu kubva mu substrate, musimboti we schematic diagram sezvakaratidzwa muFigure 1..

2. Kune yakaderera kubikira poindi yetsvina: ivhu repasi rinotora laser simba, pakarepo tembiricha yakanyanya kufashaira evaporation, yakananga vaporization kubvisa tsvina, musimboti sezvakaratidzwa mumufananidzo 2.

LaserWet CleaningPrinciple

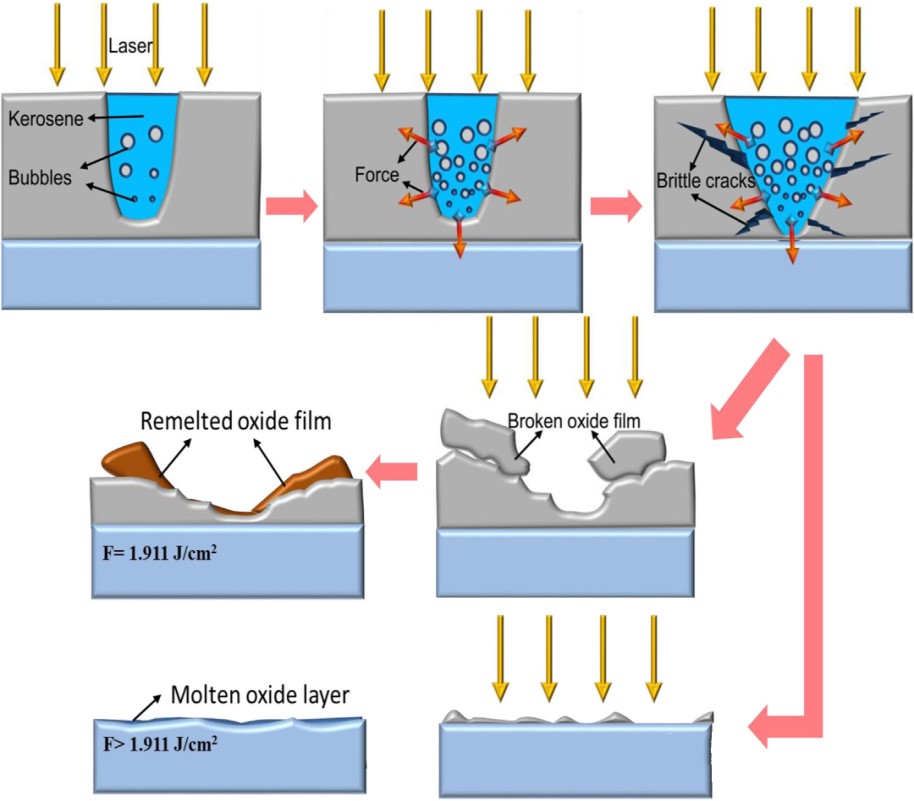

Laser wet kucheneswa kunozivikanwawo selaser steam yekuchenesa, kusiyana nekuoma, kunyorova kuchenesa kuri pamberi peiyo yakatetepa yeashoma mamicrons akakora emvura firimu kana midhiya firimu pamusoro penzvimbo dzekuchenesa, iyo yemvura firimu nelaser irradiation. tembiricha yefirimu remvura inokwira ipapo uye inogadzira huwandu hukuru hwemabhuru kune gasification reaction, gasification kuputika kunokonzerwa nekukanganisa kwezvimedu uye substrate kukunda simba rekushambadza pakati. Zvinoenderana nezvidimbu, firimu remvura uye iyo substrate pane laser wavelength absorption coefficient yakasiyana, laser wet yekuchenesa inogona kukamurwa kuita matatu marudzi.

1.Kutorwa kwakasimba kwelaser simba neiyo substrate

Laser irradiation pane substrate uye firimu remvura, kutorwa kwelaser neiyo substrate kwakakura kupfuura iyo yemvura firimu, saka kuputika kwemhepo kunoitika pakusangana pakati peiyo substrate uye firimu remvura, sezvakaratidzwa mumufananidzo uri pazasi. Nechepfungwa, kupfupika kwekufamba kwenguva, zviri nyore kugadzira kupisa kwakanyanya pamharadzano, izvo zvinokonzeresa kuputika kukuru.

2. Kutorwa kwakasimba kwelaser simba ne membrane yemvura

Nheyo yekuchenesa iyi ndeyekuti iyo firimu yemvura inotora yakawanda yelaser simba, uye inoputika vaporization inoitika pamusoro peiyo firimu remvura, sezvakaratidzwa mumufananidzo uri pazasi. Panguva ino, kushanda kwelaser kuchenesa hakuna kunaka senge iyo substrate kutorwa, nekuti panguva ino kuputika kunokanganisa pamusoro peiyo firimu remvura. Nepo iyo substrate absorption, mabhuru uye kuputika kunoitika pamharadzano ye substrate uye yemvura firimu, iyo inoputika mhedzisiro iri nyore kusundira zvimedu kubva kune substrate pamusoro, saka, iyo substrate absorption yekuchenesa mhedzisiro iri nani.

3.Ose ari maviri substrate uye iyo yemvura membrane yakabatana inotora laser simba

Panguva ino, kushanda zvakanaka kwekuchenesa kwakadzikira, mushure meiyo laser irradiation kune yemvura firimu, chikamu chelaser simba chinotorwa, simba rinoparadzirwa mukati memvura firimu mukati, iyo yemvura firimu iri kufashaira kuburitsa mabhubhu, iyo yasara laser simba. kuburikidza nefirimu yemvura inobatwa ne substrate, sezvinoratidzwa mumufananidzo. Iyi nzira inoda mamwe Laser simba kuburitsa kufashaira mabhuru kusati kwaputika. Nokudaro kushanda kweiyo nzira kwakaderera zvikuru.

Kunyorova laser kuchenesa uchishandisa substrate absorption, sezvo yakawanda yelaser simba inotorwa neiyo substrate, ichagadzira yemvura firimu uye substrate junction overheating, mabhuru pane interface, zvichienzaniswa nekuoma kucheneswa, kunyorova ndiko kushandiswa kwejunction bubble kuputika kunogadzirwa. nekukanganisa kwelaser yekuchenesa, nepo iwe uchigona kusarudza kuwedzera imwe huwandu hwemakemikari zvinhu muiri mvura firimu uye zvinosvibisa zvimedu kune kemikari kuita kudzikisa zvimedu uye substrate Iyo adsorption simba pakati pechinhu, kuitira kuderedza chikumbaridzo chelaser. kuchenesa. Nokudaro, kucheneswa kwemvura kunogona kuvandudza kushanda kwekuchenesa kune imwe nhanho, asi panguva imwechete kune mamwe matambudziko, kuiswa kwefirimu yemvura kunogona kutungamirira kune kusvibiswa kutsva, uye kukora kwefirimu yemvura yakaoma kudzora.

ZvinhuAkukanganisa theQhupenyu hweLaserCleaning

Mhedzisiro yeLaserWavelength

Iyo misimboti yekuchenesa laser ndeyekunyudzwa kwelaser, saka, mukusarudza kwelaser sosi, chinhu chekutanga kuita kusanganisa mwenje wekunyudza maitiro ekuchenesa workpiece, sarudza yakakodzera wavelength laser seye laser mwenje sosi. Pamusoro pezvo, masayendisiti ekune dzimwe nyika ongororo yekuyedza inoratidza kuti kuchenesa maitiro akafanana ezvimedu zvinosvibisa, kupfupika kwewavelength, kusimba kwekuchenesa kwelaser, kudzika kwechikumbaridzo chekuchenesa. Zvinogona kuoneka kuti, kuti isangane neyakajeka kunyudza hunhu hwenzvimbo, kuitira kuvandudza kushanda uye kugona kwekuchenesa, inofanirwa kusarudza ipfupi wavelength yelaser seyekuchenesa mwenje sosi.

Mhedzisiro yePowerDennity

Mukuchenesa laser, iyo laser simba density kune yepamusoro kukuvara chikumbaridzo uye yakaderera yekuchenesa chikumbaridzo. Mune ino siyana, iyo yakakura iyo laser simba density yelaser yekuchenesa, iyo yakakura yekuchenesa chiyero, iyo inonyanya kuoneka maitiro ekuchenesa. Naizvozvo haifanirwe kukuvadza iyo substrate zvinhu mune iyo kesi, inofanirwa kunge yakakwira sezvinobvira kuti iwedzere simba density yelaser.

Mhedzisiro yePulseWidth

The laser sosi yekuchenesa laser inogona kuenderera mwenje kana pulsed mwenje, pulsed laser inogona kupa yakanyanya simba repamusoro, saka inogona kuzadzisa zviri nyore zvinodiwa pachikumbaridzo. Uye zvakaonekwa kuti mukuchenesa maitiro pane substrate inokonzerwa nekupisa mhedzisiro, pulsed laser impact idiki, inoenderera mberi laser inokonzerwa nekupisa kwedunhu yakakura.

TheEmhedzisiro yeScanningSpeed uyeNumber ofTimes

Zviripachena mukuita kwekuchenesa laser, iyo inokurumidza iyo laser scanning inomhanyisa nguva shoma, iyo inokwirisa kugona kwekuchenesa, asi izvi zvinogona kukonzera kudzikira kwekuchenesa maitiro. Naizvozvo, mune chaiyo yekuchenesa application maitiro, inofanirwa kuve yakavakirwa pane zvinhu hunhu hwekuchenesa workpiece uye kusvibiswa mamiriro ekusarudza akakodzera scanning kumhanya uye huwandu hwema scans. Kuongorora mwero wekupindirana uye zvichingodaro zvinokanganisawo maitiro ekuchenesa.

Mhedzisiro yeAgomo reDefocusing

Laser yekuchenesa pamberi pelaser kazhinji kuburikidza nekumwe kusanganisa kwekutarisa lens yekutendeuka, uye iyo chaiyo maitiro ekuchenesa laser, kazhinji kana iri nyaya yekudzikisa, iyo yakakura kuwanda kwekudonhedza, kupenya pazvinhu zvakanyanya kukura nzvimbo, iyo yakakura nzvimbo yekuongorora, iyo yakakwirira yekushanda. Uye mune iyo yakazara simba ndeyechokwadi, iyo idiki kuwanda kwedefocusing, iyo yakakura simba density yelaser, iyo yakasimba yekuchenesa kugona.

Summary

Sezvo laser yekuchenesa isingashandisi chero makemikari zvinonyungudutsa kana zvimwe zvinodyiwa, zvine hushamwari zvakatipoteredza, zvakachengeteka kushanda uye zvine zvakawanda zvakanakira:

1. zvakasvibirira uye zvakatipoteredza, pasina kushandisa chero makemikari uye kuchenesa mhinduro,

2. kuchenesa tsvina inonyanya kuoma hupfu, hukuru hudiki, nyore kuunganidza uye kushandiswa zvakare,

3. Kuchenesa utsi hwemarara huri nyore kutora uye kubata, ruzha rushoma, hapana kukuvadza kuhutano hwemunhu,

4. Non-contact cleaning, no media residue, hapana chechipiri kusvibiswa,

5. Kuchenesa kusarudzwa kunogona kuwanikwa, hapana kukuvadza kune substrates,

6. Hapana kushanda kwepakati kushandiswa, kungopedza magetsi, mari shoma yekushandisa nekugadzirisa,

7. Easy kuwana otomatiki, kuderedza kuwanda kwebasa,

8. Inokodzera nzvimbo dzakaoma-kusvika kana nzvimbo, kune dzine njodzi kana nharaunda dzine njodzi.

Maven Laser Automation Co., Ltd. inyanzvi inogadzira laser welding muchina, laser yekuchenesa muchina, laser yekumaka muchina kwemakore gumi nemana. Kubva 2008, Maven Laser yakatarisana nekusimudzira nekugadzirwa kwemhando dzakasiyana dzelaser engraving/welding/marking/yekuchenesa muchina nehutungamiriri hwepamusoro, simba rekutsvagisa rakasimba uye hurongwa hwekudyidzana kwepasi rose, Maven Laser kumisikidza imwe yakakwana yekutengesa chigadzirwa uye sevhisi system muChina uye kutenderera pasirese, ita mhando yepasi rose muindasitiri yelaser.

Uyezve, isu tinotarisisa zvakanyanya kune mushure mekutengesa sevhisi, Sevhisi yakanaka uye yakanaka mhando yakakosha kune Maven Laser ichatevera mweya "Kuvimbika uye Kuvimbika", edza zvakanyanya kupa mutengi chakanyanya chigadzirwa uye sevhisi iri nani.

Maven Laser - yakavimbika nyanzvi Laser midziyo mutengesi!

Tikugashirei kushanda nesu uye kuwana win-win.

Nguva yekutumira: May-05-2023