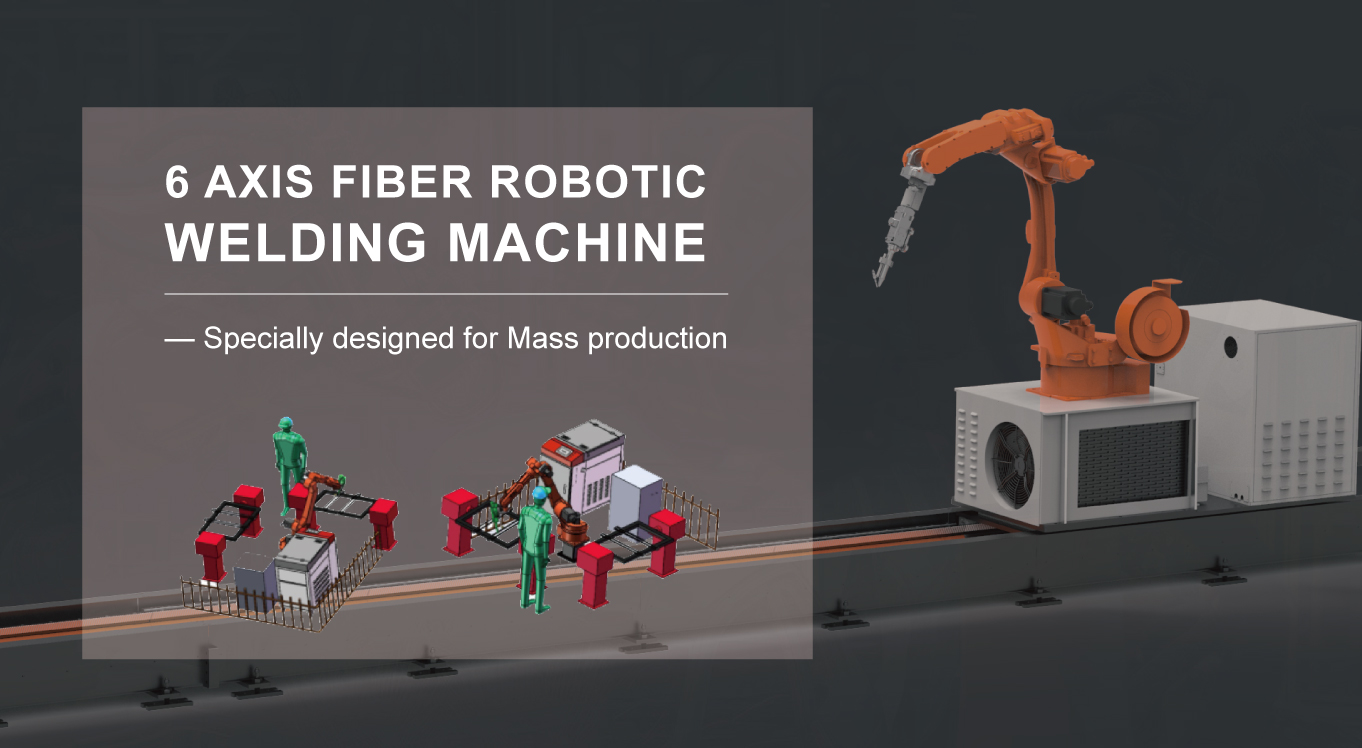

Yakakwirira Precision 6 Axis Robotic Automatic Fiber Laser Welding Machine

Equipment Features:

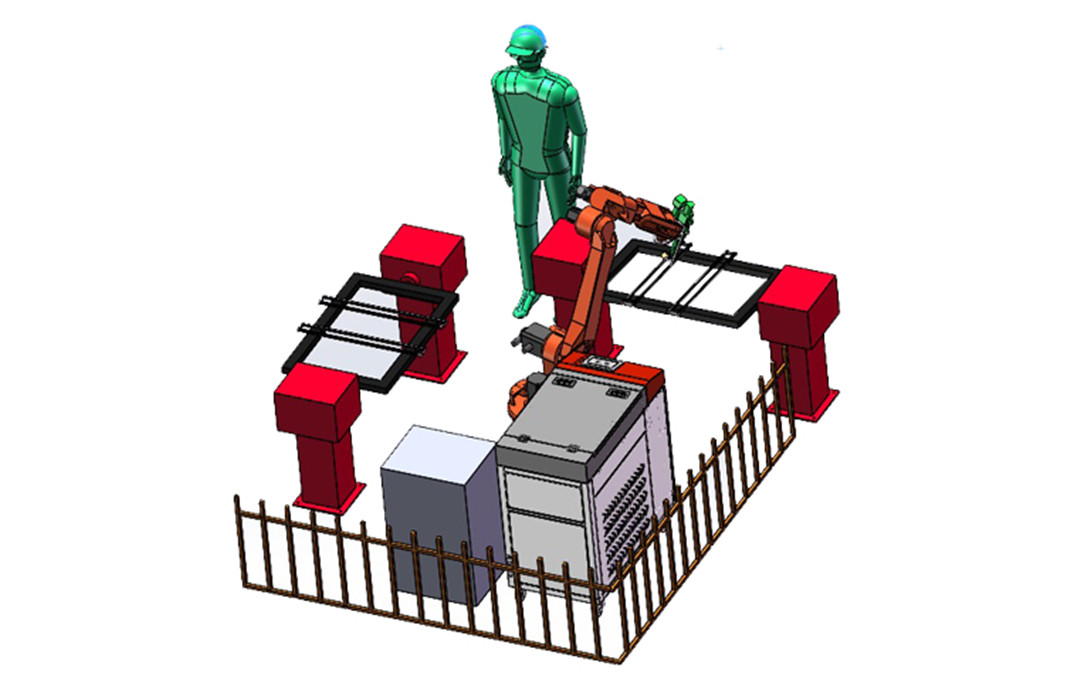

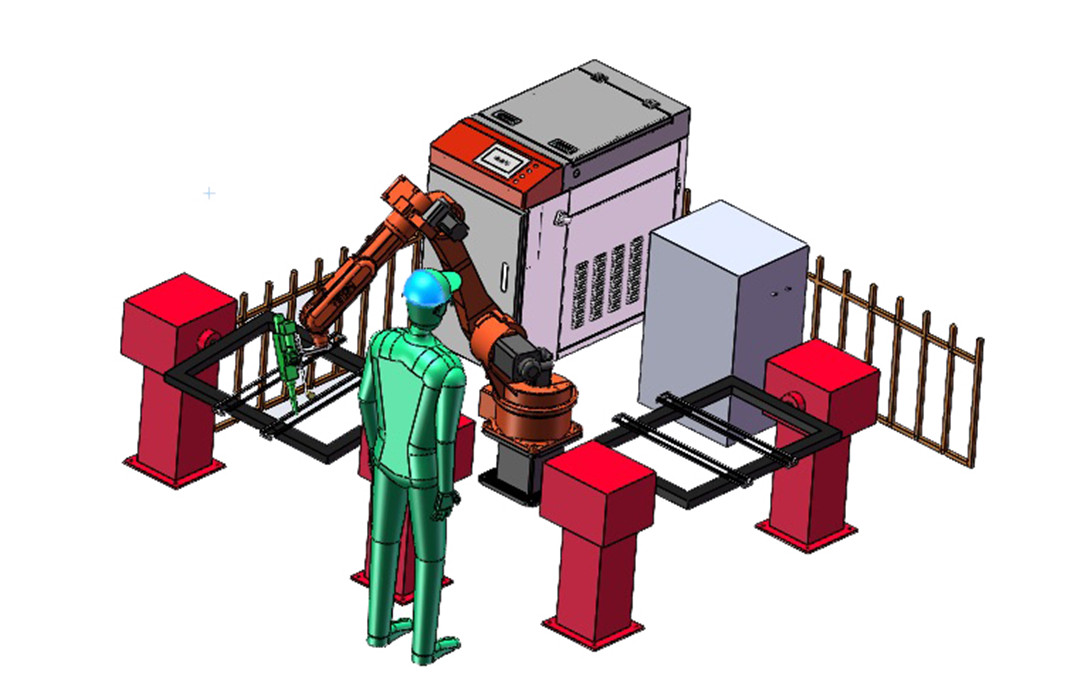

1. Kushandisa robhoti kufamba, yakakodzera yakakura-fomati nzvimbo welding, inogona kuva matanhatu-axis linkage.

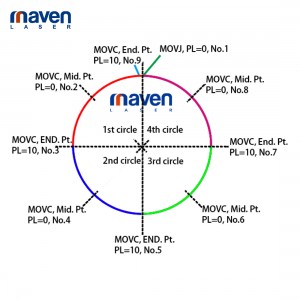

2. Inogona weld mune chero nzvimbo, zvechokwadi kuona otomatiki welding chero trajectory muchadenga.

3. Kudzokororwa kwepamusoro-soro, inogona kudzokorora welding kakawanda pasina kukanganisa, kunaka kwe weld kunowedzera kugadzikana.

4. Inogona kutsiva Chinyorwa kushanda, uye anogona Laser weld yakaoma uye ngozi minda.

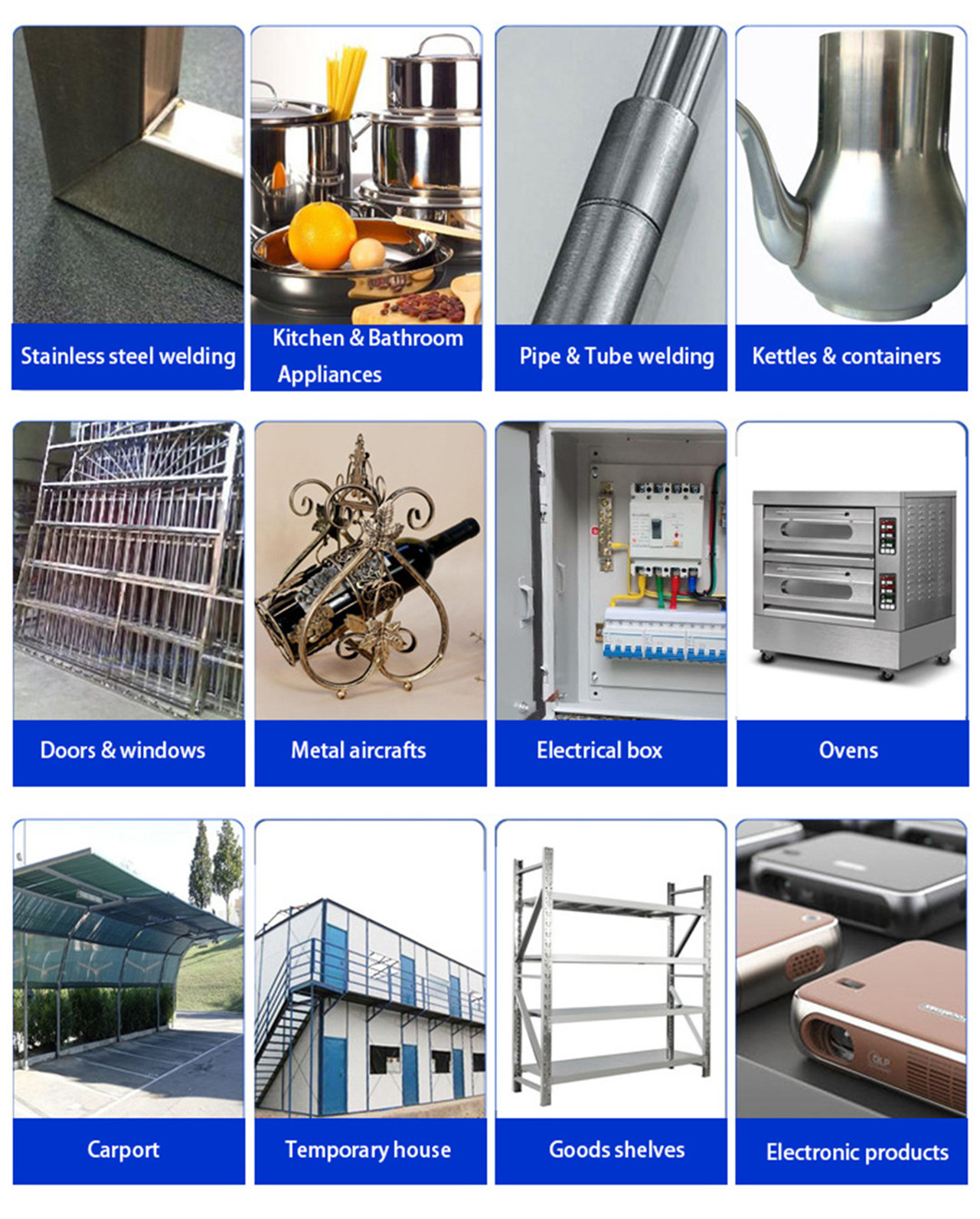

Nzvimbo dzekushandisa:

Auto body, auto simbi ndiro, clutch plate, yakaoma uye yakaoma welding minda, microelectronic components, precision parts, high-giredhi digital components, fiber optic connectors, mishonga yekurapa, hombe mold welding, jekiseni kuumba uye kumwe kuchoserwa.

PROFESSIONAL WELDING SOLUTION

Wire Feeder uye Welding Yakatarisana neKudzora Pedal

0.08mm Robot Positioning Kururama

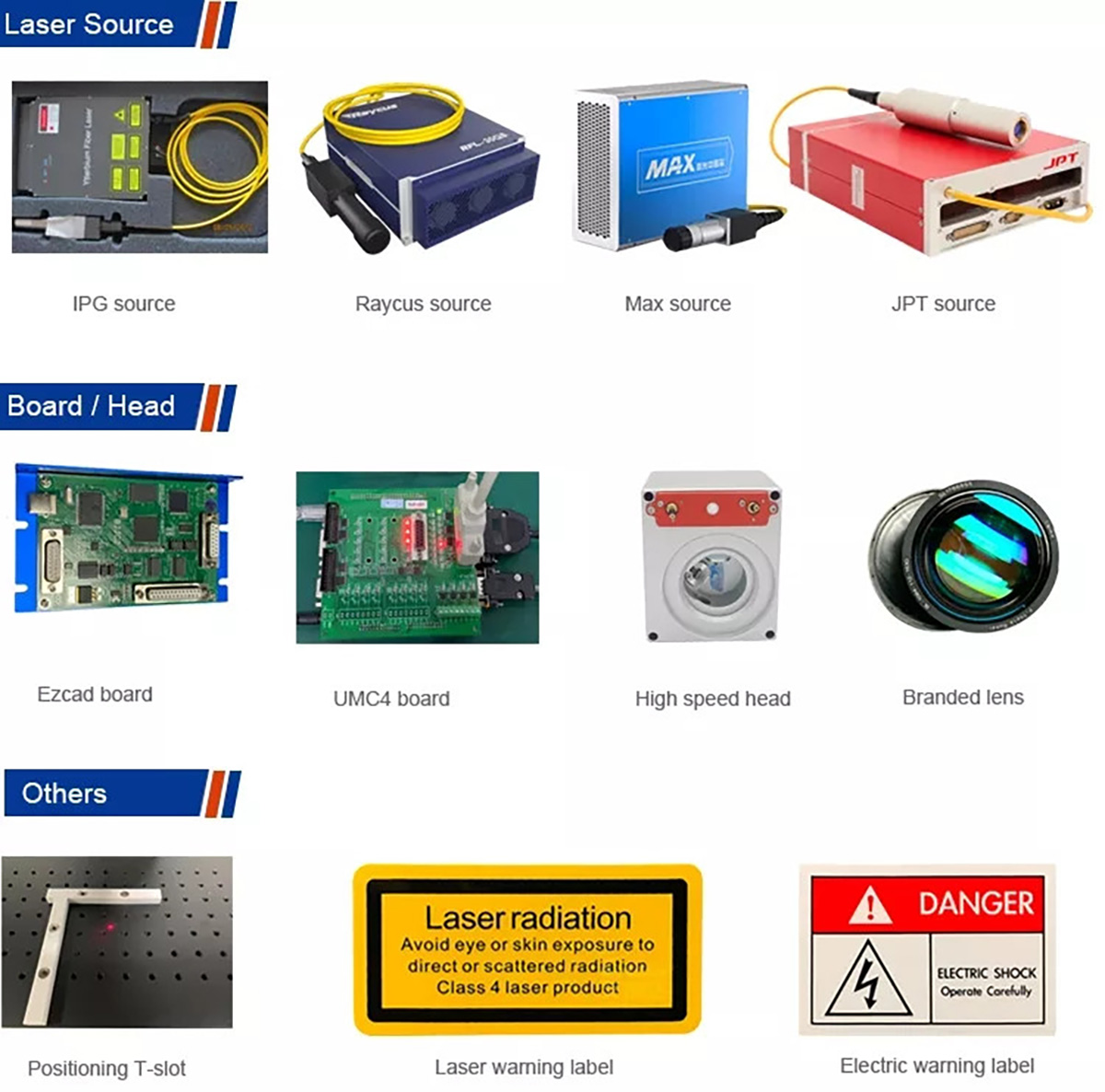

Raycus Max JPT IPG Laser Source Optional

Kugadziriswa kweYese System

| Product Name | Robhoti otomatiki Laser Welding MachineMLA-W-A01 |

| Wavelength | 1070+/-10 nm |

| Laser Simba | 1000W 1500W 2000W 3000W |

| Kugadzirisa Simba | 10-100% |

| Fiber Length | Standard 10m kana Taura |

| Mashandiro Nzira | CW/Pulse |

| Speed Range | 0-120 mm |

| Weld Kukora | 0.5-6 mm |

| Welding Gap Chinodiwa | < 1 mm |

| Modulation Frequency | 20KHZ |

| Batidza/dzima Nguva | 20 Isu |

| Kushanda Tembiricha | 15-35 ℃ |

| Magetsi | 220V/50HZ/30A |

| Chilling Nzira | Mvura Inotonhorera Inbuilt |

| Machine Size | 990*540*1030 mm |

ZVINYORE KUSHANDISA

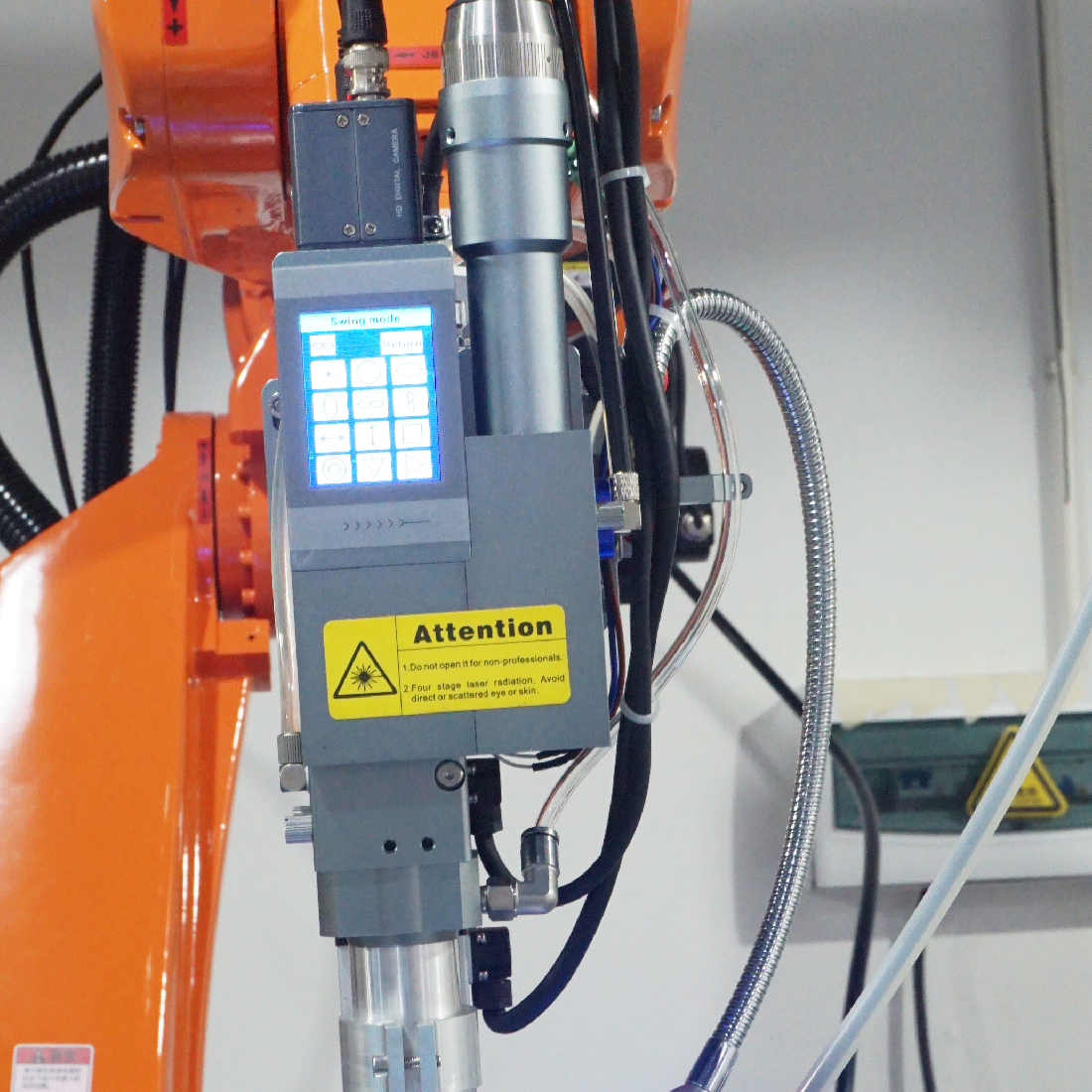

Hushamwari shandisa controller yekudyidzana nyore nefiber laser welding workmanship rairo

KUDZORA INTERGATION

Iyo yekudzora kabati yekubatanidza ndeye kudzora waya yekudyisa basa. Uye iyo laser simba inogona kusimuka uye inodonha zvishoma nezvishoma kudzivirira pamusoro pekupisa. Iko kunonoka kusimuka nekudonha kunonyanya kubatsira kune yakaonda plate welding. Kana iyo manipulator ichipedza, kazhinji zviri nyore kupinza mundiro.

LASE INTERGRATUION

Pamusoro pekugadzirisa iyo welding parameters mune laser system. Iyo ine zvakare mabasa ega yega system chimiro chiratidzo mwenje, yemagetsi shanduko yemvura, uye otomatiki chiyeuchidzo kuchengetedza lens.

KUBATANA MUSORO

Yakabatanidzwa welding musoro, CCD pamusoro, inogadziriswa simba, auto kutarisisa, kushanda kuri nyore.

ZVINYORE KUSHANDISA

Mabhatani eiyo pendant yekudzidzisa ari nyore uye ari nyore kunzwisisa, uye chirongwa chekudzidzisa chinogona kudzidzwa uye kushandisa nekukurumidza. Kana oparesheni yacho isiriyo, muchina unomira wega kudzivirira njodzi yekukuvadzwa kwemidziyo.

SHANDA NEZVINHU

Kana yangogadzirwa, inogona kushandiswa nguva dzese. MavenLaser Robot Arm inotsigira maawa makumi maviri nemana ekuenderera mberi kwebasa nehupamhi hwepamusoro uye nekumhanya kwakanyanya. Kunyatsoshanda otomatiki, robhoti inogona kupedzisa basa revanhu vanopfuura 2-3 pazuva.

MUTENGO WAkaderera

Imwe-nguva yekudyara, mabhenefiti enguva refu. Hupenyu hwesevhisi yeMavenLaser robhoti i80,000 maawa, ayo akaenzana neanopfuura makore 9 emaawa makumi maviri nemana ebasa risina kukanganiswa. Inochengetedza zvakanyanya mutengo wevashandi uye mutengo wekutonga kwevashandi, uye inogadzirisa matambudziko akadai sekuomerwa mukutora vanhu.

AKAKONZERA UYE AKATENDEKA

MavenLaser robhoti ruoko rwakashongedzerwa nephotoeletric kuchengetedza matanho. Kana zvinhu zvekune dzimwe nyika zvikapinda munzvimbo yebasa, inogona otomatiki alarm uye kumisa basa kudzivirira tsaona mumushandi.

SIMBA RAKAKONZERA UYE RUNYANYA

MavenLaser otomatiki michina mutsara dhizaini iri nyore uye yakarongeka diki tsoka, hapana ruzha, yakareruka uye yakasimba robhoti ruoko, yakaderera simba kushandiswa, simba saxing uye kuchengetedzwa kwezvakatipoteredza.

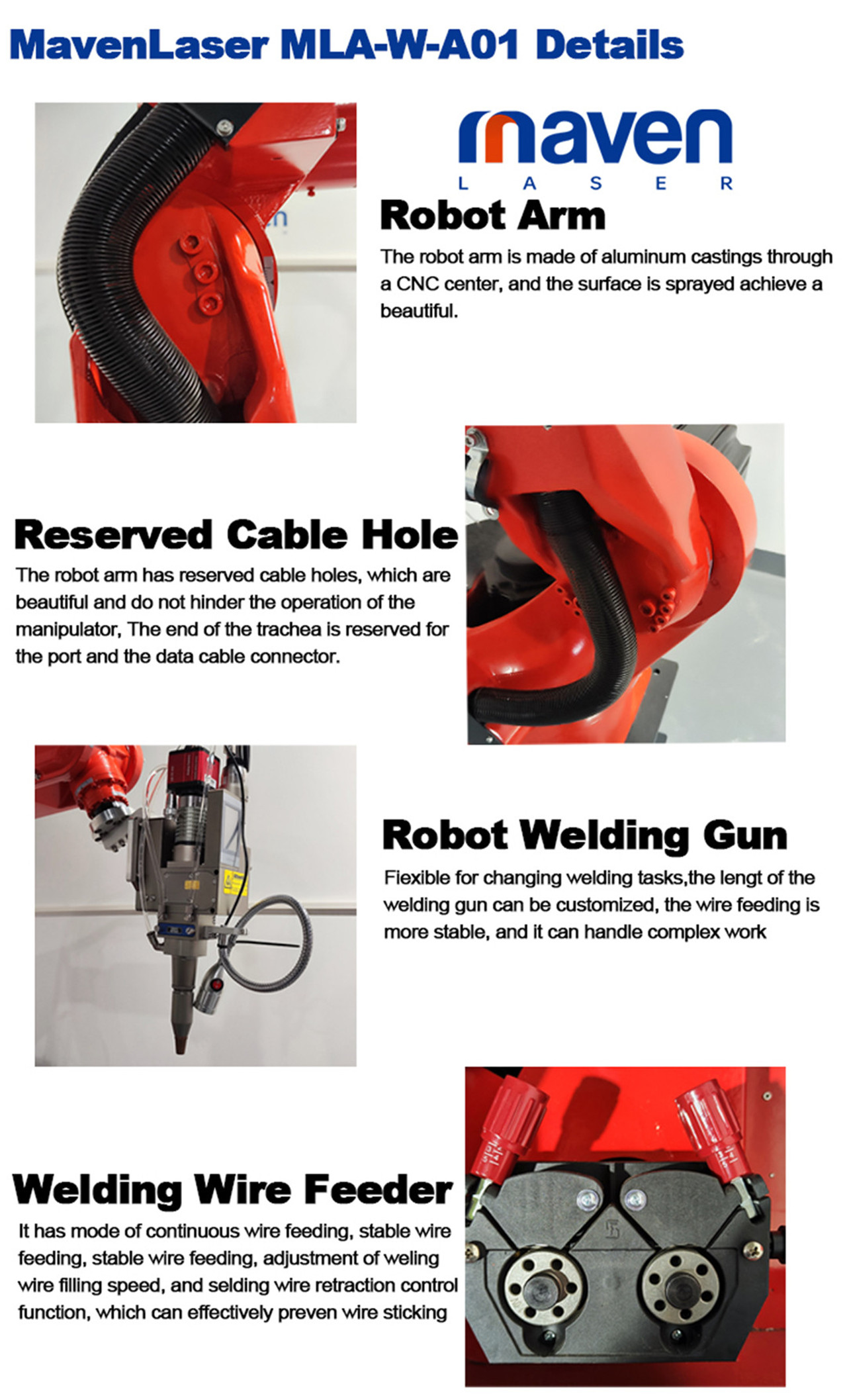

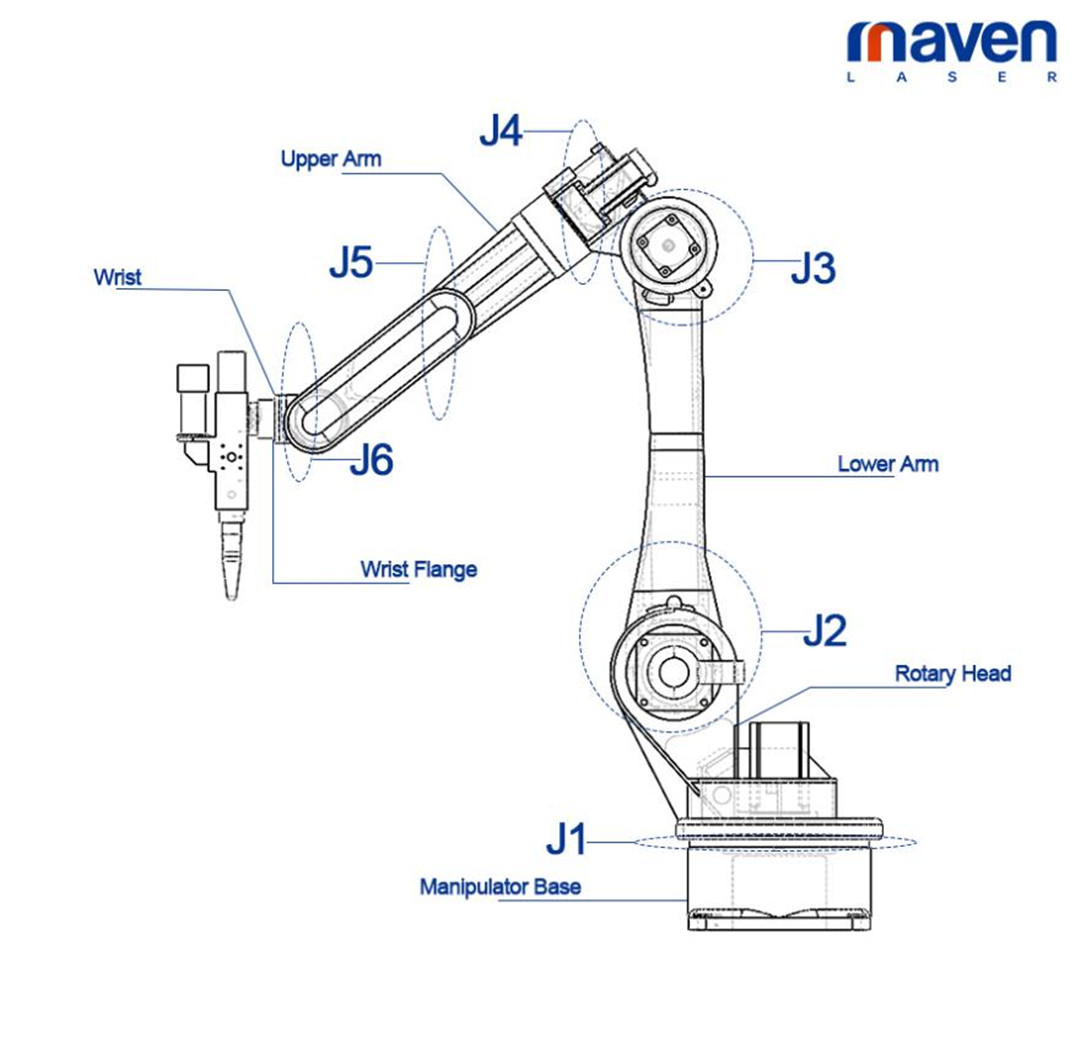

Robhoti Arm

Ruoko rwerobhoti rwakagadzirwa nealuminium castings kuburikidza neCNC centre, uye iyo nzvimbo yakapfapfaidzwa inowana yakanaka.

Reserved Cable Hole

Ruoko rwerobhoti rwakachengeta maburi etambo, ayo akanaka uye nit anotadzisa kushanda kweiyo manipulator, kuguma kwetrachea kwakachengeterwa chiteshi uye data cable yekubatanidza.

Robhoti Welding Pfuti

Flexible yekuchinja welding mabasa, kureba kwepfuti yekushongedza inogona kugadziridzwa, iyo waya yekudyisa yakagadzikana, uye inogona kubata basa rakaoma.

Welding Wire Feeder

Iyo ine maitiro ekuenderera mberi kwekudya kwewaya, yakagadzika waya yekudyisa, yakagadzikana waya yekudyisa, kugadzirisa kweyakanaka waya yekuzadza kumhanya, uye kutengesa waya yekudzoreredza kudzora basa, iyo inogona kunyatso kudzivirira waya inonamira.

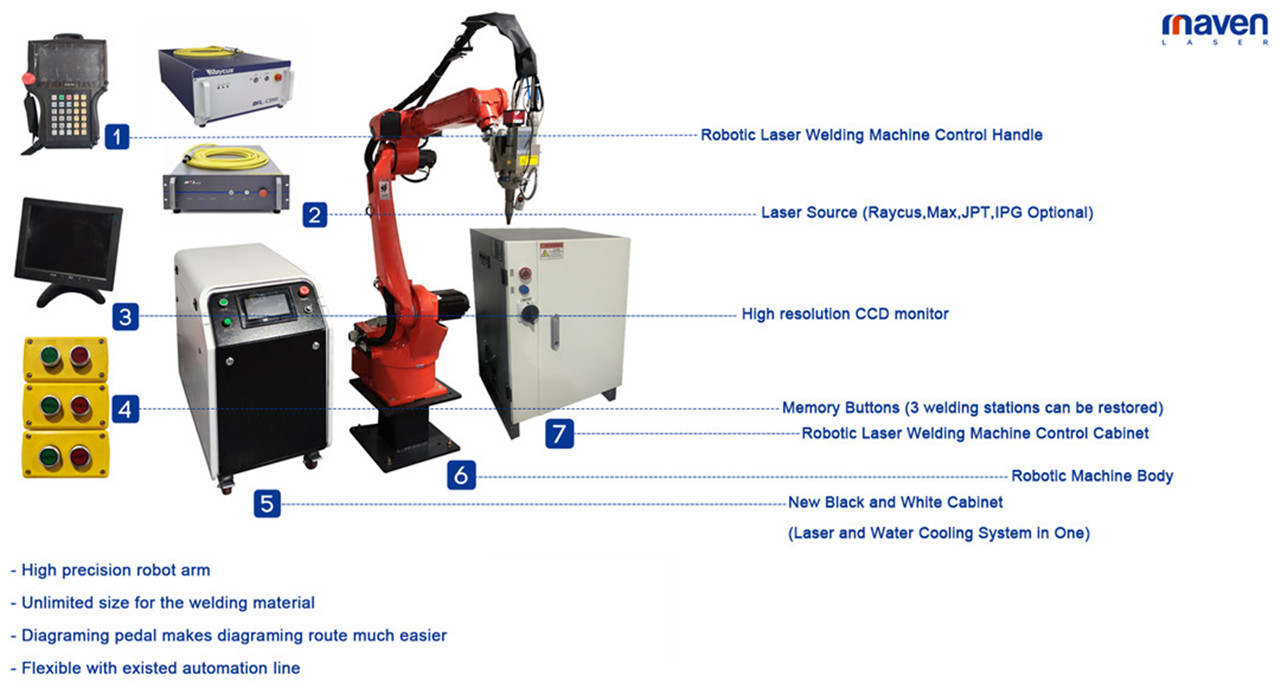

● Laser Source(Raycus,Max,JPT,IPG Optional)

● High resolution CCD monitor

● Memory Button (3 welding stations inogona kudzorerwa)

● New Black and White Cabinet (Laser uye Mvura Kutonhora System mune Imwe)

● Robotic Machine Body

● Robotic Laser Welding Machine Control Cabinet

● Ruoko rwemarobhoti rwepamusoro

● Unlimited size ye welding material

● Diagramming pedal inoita kuti nzira yedhiyagiramu ive nyore

● Flexible ine iripo otomatiki tambo

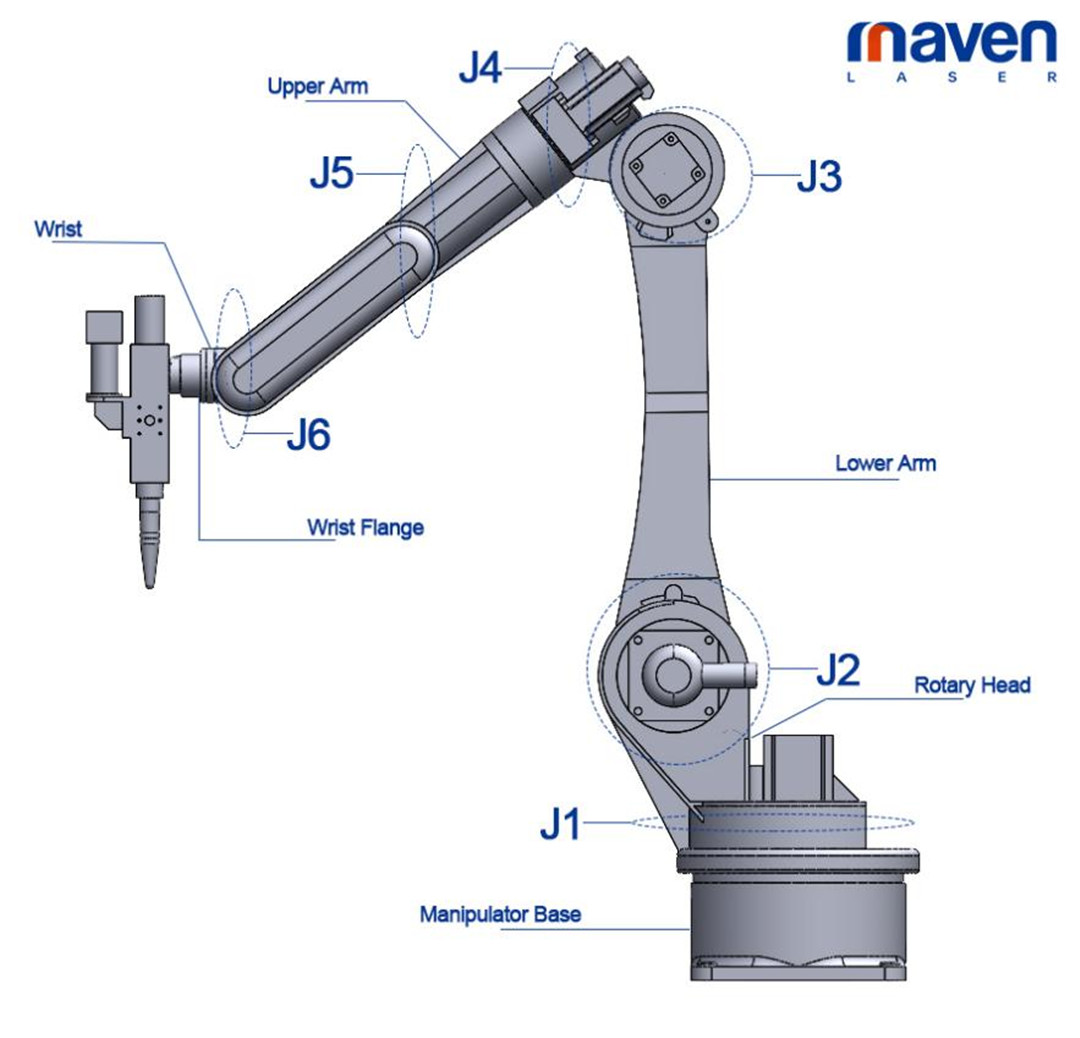

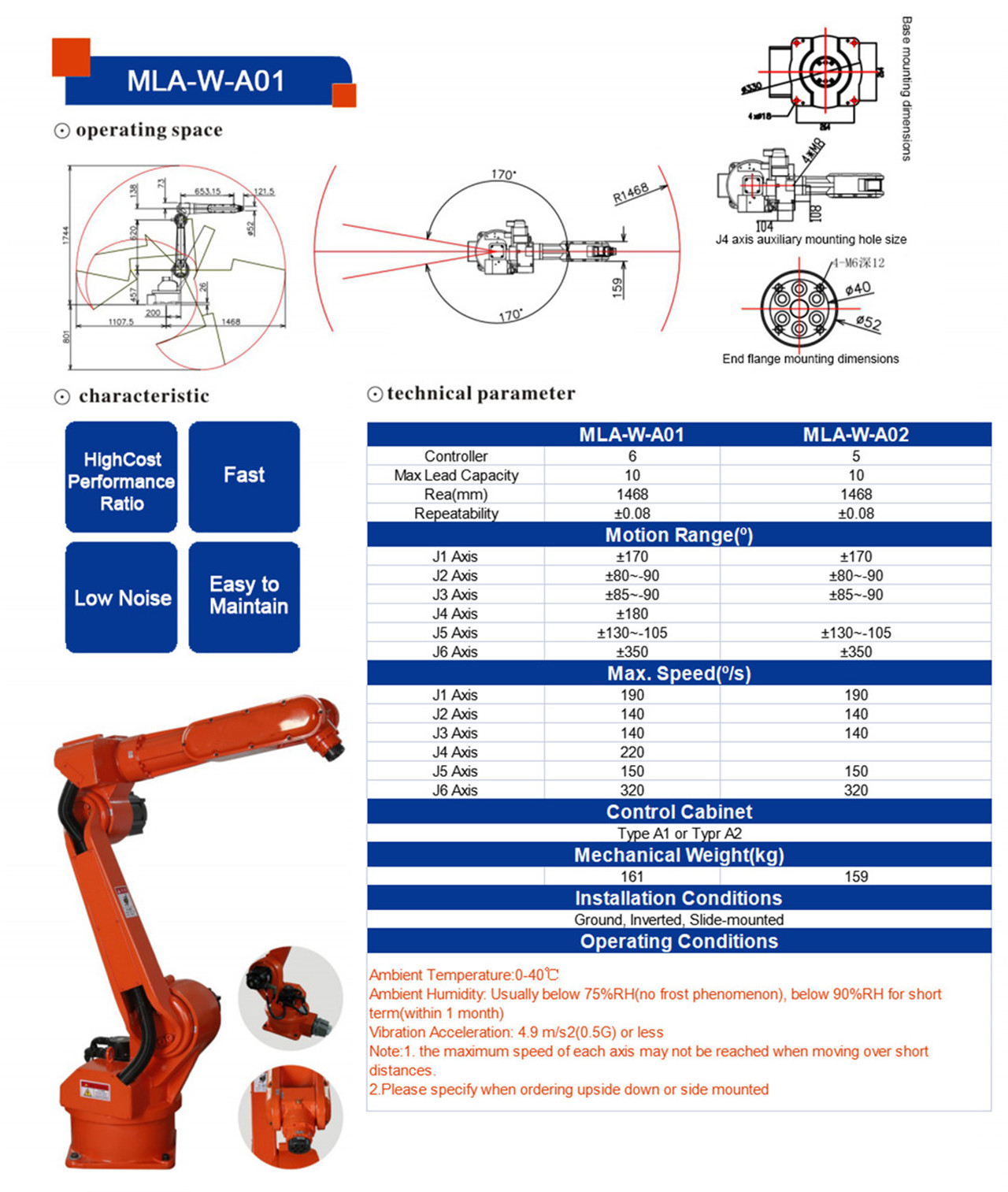

| MLA-W-A01 | MLA-WA02 | |

| Controller | 6 | 5 |

| Max Lead Capacity | 10 | 10 |

| Rea(mm) | 1468 | 1468 |

| Kudzokorora | ±0.08 | ±0.08 |

| Motion Range(°) | ||

| J1 Axis | ±170 | ±170 |

| J2 Axis | ±80~-90 | ±80~-90 |

| J3 Axis | ±85~-90 | ±85~-90 |

| J4 Axis | ±180 |

|

| J5 Axis | ±130~-105 | ±130~-105 |

| J6 Axis | ±350 | ±350 |

| Max. Kumhanya (°/s) | ||

| J1 Axis | 190 | 190 |

| J2 Axis | 140 | 140 |

| J3 Axis | 140 | 140 |

| J4 Axis | 220 |

|

| J5 Axis | 150 | 150 |

| J6 Axis | 320 | 320 |

| Kudzora Cabinet | ||

| Type A1 kana Type A2 | ||

| Mechanical Weight(kg) | ||

|

| 161 | 159 |

| Installation Conditions | ||

| Ground, Inverted, Slide-yakaiswa | ||

| Operating Conditions | ||

Ambient Tembiricha:0-40℃

Ambient Humidity: Kazhinji pasi pe75%RH(hapana chando chiitiko), pasi pe90%RH kwenguva pfupi (mukati memwedzi mumwe)

Vibration Acceleration::4.9 m/s2(0.5G) kana zvishoma

Cherechedza: 1.kumhanya kwepamusoro kweakisi imwe neimwe inogona kusasvikwa kana ichifamba pamusoro pezvinhambwe zvishoma.

2.Ndapota tsanangurai paunenge uchiraira kumusoro pasi kana rutivi rwakaiswa

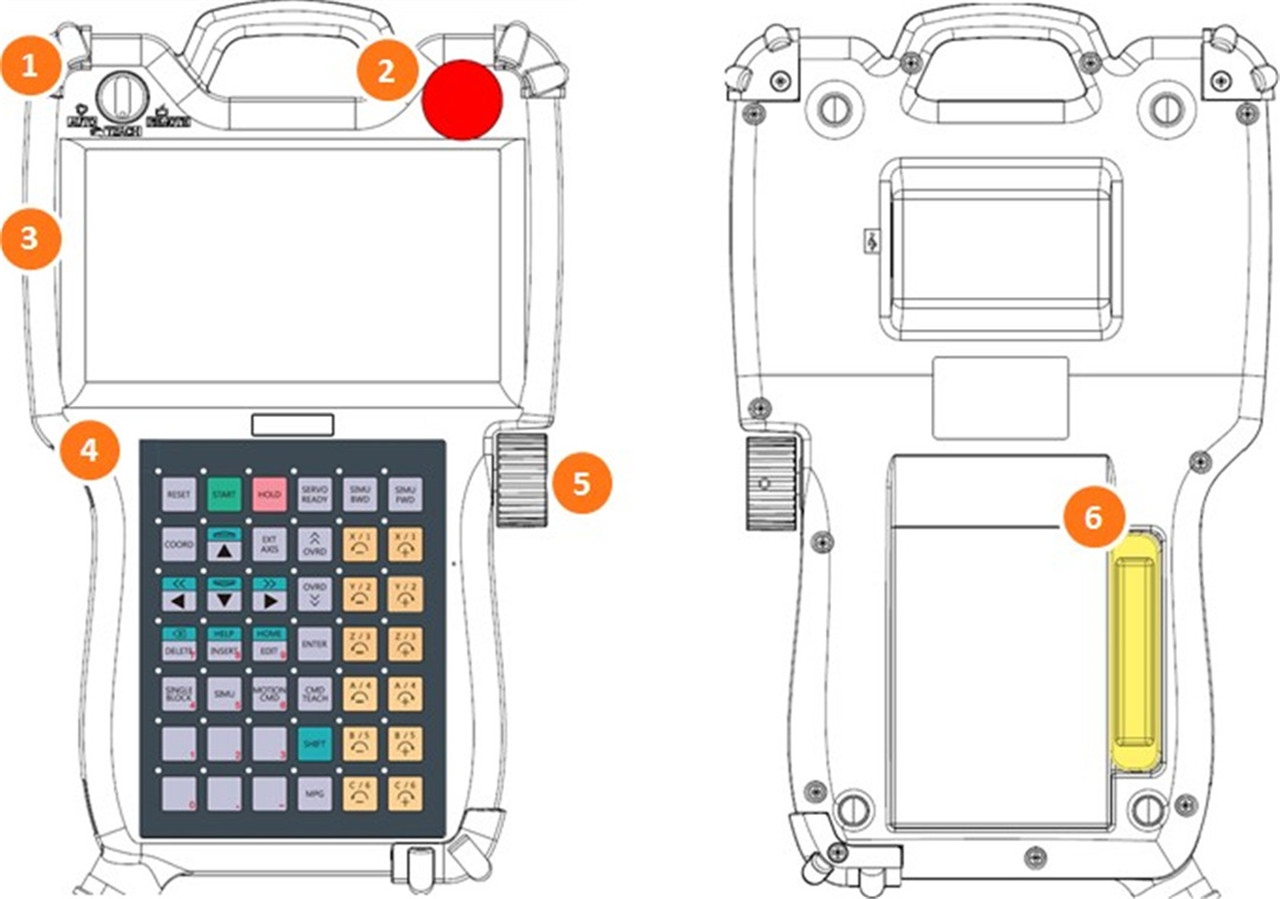

1. Mode Switch

2. Emergency Stop

3. Ratidza Sikirini

4. Physical Keys

5. MPG (Manuel Pulse Generator)

6. Inogonesa Chigadzirwa